ndpetrify4's blog

In the casting industry, investing in casting refers to the process of putting money into investments, which is defined as follows:

Investment casting, also known as lost wax casting, is a sophisticated metal forming process that can be used to create both solid pieces and hollow cores from metal. It can be used to create both solid pieces and hollow cores from metal. It can be used to create both solid pieces and hollow cores out of metal, depending on the application. Depending on the application, it can be used to fabricate both solid pieces and hollow cores out of metallic materials. Our disposable templates are used to manufacture high-quality metal components that can be thrown away after they have been used.

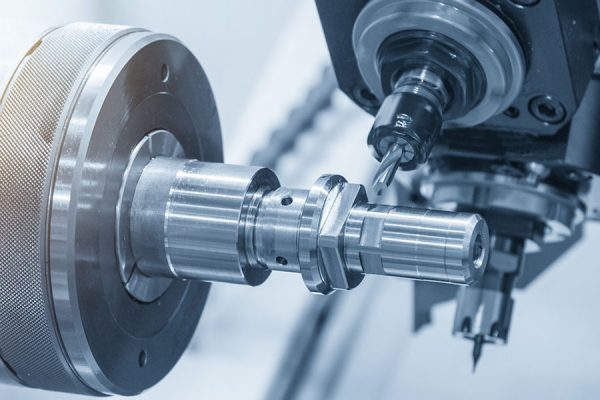

It is possible to create a pattern by injecting wax into a metal die, which is done with the help of a special tool. In fact, this pattern is a carbon copy of the final section of the project's final section, down to the smallest detail. In order to harden the surface and hollow them out for use in other applications, the castings are waxed and then fired at a high temperature after the ceramic has been applied. The mixture is then poured into the hot cast exterior shell of the mold, which is then finished in the following step to complete the mold construction process. Before disposing of the metal, it is necessary to blast away each and every piece of ceramic that has adhered to it. Material evaluation can be accomplished through a variety of techniques, including chemical, physical, and nondestructive testing (NDT).

During the process of casting services, a mold is filled with sand, which is then poured into the mold to produce a finished piece of metal.

Those interested in mold-making should be aware that sand casting is a technique that involves using finely ground spherical grains that are tightly packed together on a smooth molding surface to create a mold for a variety of materials. When it comes to producing both large and small pieces of artwork, it is a low-cost method of production.

Machine casting pieces in conjunction with a sand core box should be considered, as should sand core boxes and wooden or metal patterns in addition to the machine casting pieces. Pouring the component into a sand mold is the first step in the molding process. Pouring the component is the term used to describe this process. After the metal has cooled, it is blasted or otherwise surface treated in order to remove any remaining imperfections and bring the machining procedure to a successful conclusion.

Die casting is the process of pressing a solid piece of metal through a die to form a solid piece of metal. Die casting is one of the most common types of metal casting and is used in a variety of applications.

A variety of die casting processes are available to customers in the metal die casting industry. These processes include cold chamber die casting, hot chamber die casting, and multi-slide hot chamber casting, to name a few. Hot chamber die casting is a technique that is commonly used in the large-scale production of magnesium, zinc, and other low-melting-point alloys, as well as other metals. The use of cold chamber die casting is a viable and increasingly popular alternative for metals with high melting points, such as aluminum and magnesium.

Die casting is made possible by the use of metal alloys such as aluminum, zinc, and magnesium, each of which has its own set of characteristics. Die casting is made possible by the use of metal alloys such as aluminum, zinc, and magnesium. These materials provide a significant amount of shielding protection against EMI/RFI radiation when it comes to shielding protection.

Die casting services have a number of advantages, the most notable of which is that they enable the creation of complex shapes such as external threads, which would otherwise be impossible to achieve using other methods. Die casting services are available in a variety of sizes and shapes. Aside from being more cost effective, die casting services are also less expensive than other methods. Two of the advantages that can be obtained as a result of this are the reduction of secondary operations and the reduction of production costs. Die casting offers a number of additional benefits, the most notable of which are as follows:

The reduction in the number of steps between raw materials and finished goods results in a significant increase in the production speed of finished goods.

This has had a significant impact on the price of scrap metal, which has fallen significantly.

It is necessary to have extremely tight tolerances in order to function properly.

The wall thicknesses can be customized to meet your requirements.

Because of this, the surface finish and stability of the product are improved, and the product's lifespan is lengthened as a result.

The process of mold casting is accomplished through the use of a permanently installed mold.

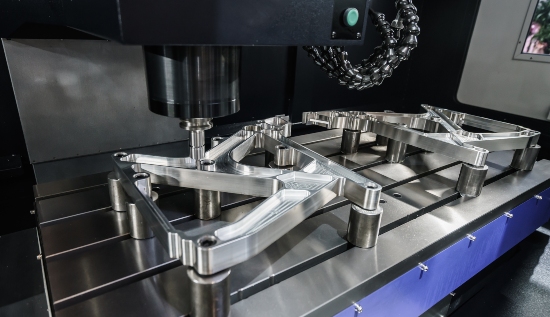

In the process of making permanent molds for metal casting, permanent or reusable molds are created by milling mold cavities into metal die blocks and then modifying them so that they can be re-used multiple times. It is necessary to use these molds in order to shape liquid casting metals into the desired part or component of the final product.

In order to ensure that the overall dimensional stability of the product is maintained, mold casting services for permanent molds are utilized. The finished casting is much closer to its final specification than the raw casting services so the machining tolerances for finished castings are smaller than those for raw castings as a means of compensating for this. Due to the higher density and tightness of the castings produced by this process compared to those produced by other methods, the amount of finishing and surface treatment required is reduced, resulting in savings in terms of both time and money, as well as increased productivity.

Using plaster as the primary casting material is a type of casting in which the plaster material is used as the casting material itself.

It is possible to create objects out of plaster using a technique called plaster casting, which is similar to sand casting. It is possible to make a concrete substitute out of water, calcium carbonate, and a strengthening additive in order to give the concrete more strength when sand is not available. Abbott Interfast has gained the trust of numerous well-known and respected corporations in the aerospace and appliance industries, as well as the consumer goods and telecommunications industries, as a result of this. If you require any additional information, please do not hesitate to contact us.

It is possible to work in several different casting industries, each with its own set of applications.

It is extremely adaptable and can be found in a wide range of industries, including the automotive industry, demonstrating its versatility.

Electronics destined for use in the medical and automotive industries, among other applications

WMDs (weapons of mass destruction) are a type of nuclear weapon that can kill millions of people.

Electronic communications equipment is utilized in the industrial market.

Throughout history, numerous great artists have painted on a variety of unusual surfaces, including a variety of unusual surfaces, as well as a variety of unusual surfaces, as well as a variety of unusual surfaces, as well as a variety of unusual surfaces, as well as a variety of unusual surfaces, as well as a variety of unusual surfaces, as well as a variety of unusual surfaces, as well as a variety of unusual surfaces, as well as a variety of unusual surfaces, as well as a variety of unusualNatural materials such as stone, wood, and glass, rather than more traditional media such as canvas or paper, were used to create the artworks. The artists opted to work with natural materials such as stone, wood, and glass rather than more traditional media such as canvas or other types of paper in order to express themselves more fully. Please consider the following examples to gain a better understanding of what this means in your everyday life.

Because it is manufactured with an ultra matte finish on both sides, it appears to be frosted on both sides when viewed from different angles. This is accomplished by applying an ultra matte finish to both sides of the panel, giving the panel the appearance of being frosted in appearance. To achieve the desired frosted appearance on both sides of the panel, freighted Plexiglass is manufactured with an ultra matte finish on both sides of the panel, which is important to remember. Because of the ultra matte finish on both sides of the panel, it can be used to create the appearance of frosted glass on both sides of the panel when viewed from different angles. Acrylic paint that is applied to both sides uses of acrylic plastic while it is drying will adhere to both sides of the sheet and form a strong bond between the two pieces of acrylic paint that are applied to both sides of the sheet. This flexibility in terms of adjusting the clamps makes it possible to make certain that the Plexiglas is in the proper position for your specific project.

Using a specialized cleaner such as Novus #1 to thoroughly clean the surface is recommended before painting over an acrylic surface. Alternatively, thoroughly cleaning the surface with water and dish soap is recommended before beginning to paint over an acrylic surface. It is non-toxic and does not cause any pollution to the environment in any manner. No toxins are released into the environment, and it does not pollute the environment in any way. There are no toxins released into the environment, and the environment is not polluted in any way as a result of this process. Aside from the fact that no toxins have been released into the environment, there has been no pollution of the environment as a result of this process.

Acrylic painting techniques, suggestions, and tips to help you have a successful painting session are covered in this article: learn how to create beautiful paintings using acrylic paint.

Please let me know if you require any additional assistance before we begin. Thank you for your understanding. Thanks for taking the time to read this. Thank you for reading this and taking the time to do so. Thank you for taking the time to read this and for your consideration. Thank you for taking the time to read this and for taking the time to consider my request. I appreciate your consideration.

Many different variables must be taken into consideration. Access to the market and distribution are most advantageous to brands that have a distinct and differentiated point of view, and these brands reap the greatest rewards as a result of their efforts. Businesses must take advantage of every opportunity that presents itself to them in order to establish themselves as having a truly distinctive appearance that presents itself in their market niches over time. The most effective way to accomplish this is through the use of Wholesale Packaging Boxes that have been personalized. With the current economic climate, it is impossible to overestimate the profitability of these boxes. Companies can draw the attention of their target market to their products by placing them in these boxes. There is a direct relationship between the amount of attention paid to a brand's sales efforts and how successful the brand's sales efforts have been.

By checking these boxes, brands can influence the competitive landscape in which their businesses compete as a result of their actions. This strategy is being promoted by brands in order to increase sales and generate more interest among customers. Because of the use of these boxes, it is possible for us to accomplish this. Individuals in positions of authority have a significant impact on the overall outlook for the country. This transformation also results in the brands involved having a completely different and more appealing appearance and feel as a result of the transformation. Both product marketing and brand marketing are improved as a result of this procedure, which has a positive impact on both.

Low-cost custom wholesale boxes offer a significant advantage over other alternatives in terms of functionality and cost.

Uncontestable evidence exists that the services and attention provided by these boxes are of the highest possible caliber, and this documentation is readily available. Because of the way they appear, these boxes have an impact on the overall design of the page. Because of the shift in perspective, how a product is perceived in the marketplace can change as a result of the shift in perspective. This type of packaging gives products a more finished and professional appearance, which in turn encourages buyers to treat the product with greater respect as a result of the improved presentation. A significant amount of money could be made from the sale of these boxes.

If you want to be considered for this promotion, your Customized Boxes with Logo must have your company's logo prominently displayed on the outside of the container.

If an organization is concerned with increasing sales and marketing, having the capability of printing its logo on packaging boxes can be extremely beneficial to its overall health and success. This is especially true if the organization is concerned with increasing sales and marketing. Companies stand to gain significantly as a result of this development. It is necessary to position Customized Boxes with Logo in such a way that the logo is as large and impressive as possible before placing them on the product in order for them to be effective when placed on the product. Having a sophisticated and contemporary design, as well as strategically placed boxes, are required in order to make effective use of this feature.

When it comes to maintaining a competitive edge while also playing safely, the use of cigarette wholesale boxes can be extremely beneficial.

If you look at the current state of product quality, many of the brands currently available on the market are doing an excellent job in this area. Since the time the products and brands in question were first introduced to the market, there has never been any question about their superiority in terms of quality. Taking all of these considerations into consideration is critical. The way a person approaches their life is even more important than their physical health, and this is something that should not be overlooked. In an ideal world, brands would avoid engaging in this practice at all costs. Unfortunately, this is not the case. Purchase of Wholesale Packaging Boxes, to be more specific, can be extremely beneficial in this situation. A large number of years are almost certain to pass before these storage containers are decommissioned. These individuals wield a significant amount of authority in their respective roles.

In addition to providing brands with a professional appearance, these boxes also enable them to maintain their position in the face of constantly changing marketing fashions and trends, which is essential for remaining competitive. The fact that they are inconsequential details in the grand scheme of things does not diminish their importance. It has an impact on everyone and everything, and the outlook reflects how much of an impact it has had. By making use of these boxes, which are particularly important in a market that is constantly changing and where trends are everything, we can instill confidence in our product and ensure that it remains extremely simple and cost-effective in the marketplace. The level of competition that exists between businesses is one of the aspects that are taken into consideration.

Detailed instructions on how to make proper use of cigarette wholesale boxes can be found on the following page.

In order to complete the implementation of these innovative and creative boxes, it will take a significant amount of time and effort. The considerations that must be taken into account when brands compete for placement in these boxes are numerous and complicated to explain. In some cases, these tasks are required to be completed, whereas in others, it is highly recommended that they be skipped or avoided entirely, depending on the circumstances. In this context, it is critical to use contemporary and fashionable fonts, for example. This means that they must make a concerted effort to stay abreast of the most recent technological advancements. An analogous statement can be made about the natural game of colors and contrasts that takes place in the world around us every day. When it comes to choosing colors for their products, brands must exercise caution in order to be considered cool and appropriate. The designers' insufficient color selection has resulted in a reduction in the overall coolness of the product as a result of their efforts.

Aluminized products are made by heating aluminum until it becomes liquid, then pouring the liquid into a mold to form the desired shape. Because alloy steel is more corrosion resistant than aluminum and has a lower freezing point than steel, it is typically used in the mold's construction because it is more corrosion resistant than aluminum. Alloy steel is more corrosion resistant than aluminum and has a lower freezing point than steel. The use of sand as a mold material for aluminum casting is another common practice. Sand can be found in a variety of places and is relatively inexpensive to purchase. By pressing the sand into the desired shape, the sand is transformed into the desired shape. It is then necessary to incorporate the liquid aluminum into the mixture, which must then be allowed to cool completely before the process can proceed.

Alumina layer forms quickly on the surface of aluminum castings after they are cast, acting as a corrosion-resistant barrier between the aluminum castings and their surrounding environment.

Both ingot casting and mold casting are terms that are used to describe the processes that are used to create aluminum alloys. Ingot casting is a term that is used to describe the processes that are used to create aluminum alloys. When it comes to creating aluminum alloys, the term "ingot casting" is used to describe the processes that are employed. Many different techniques are available for joining the sand molds together, but the two most common are described in greater detail below.

When making green sand, a combination of sand, clay, and moisture is used, and this particular type of sand is known as green sand because of its green color.

It is used in the production of dry sand (a type of concrete), which is made up of finely ground sand and synthetic binders that have been thermally or chemically cured before being placed in the ground.

For the purpose of fabricating hollow parts of castings that will be used to fill in the gaps between the overall shape of the casting and the hollow parts of the casting, it is necessary to use a mold in conjunction with dry sand components and a mold.

When it comes to high-volume manufacturing environments, this highly adaptable technique is the one that is most frequently employed. A wide range of materials, including metals, ceramics, polymers, and composites, are created using the Dolin Casting process, which includes the following:Aluminum Sand Casting Techniques and Methods: There are a variety of options.

Such molds are typically filled with molten metal through a filling system, which allows for a more consistent filling system. When the low pressure sand casting technique is used to cast the part, a small temperature difference between the two parts of the mold is created, and the molten metal is forced into the mold as a result of the temperature difference. In addition to traditional die casting processes, such as vacuum die casting and squeeze casting, a growing number of new die casting processes are emerging, with the importance of contributions from vacuum die casting and squeeze casting processes increasing over time. The aluminum casting process that is most appropriate for your requirements should be chosen.

A specialty of Dolin Casting is the production of castings for a variety of applications. The company specializes in both sand casting and permanent mold castings. Each factor will be considered, and the best process will be selected based on how well it meets the requirement. a.

The automated sand casting technologies used by Dolin Casting Manufacturing are superior to those used by permanent mold operations because they can produce a large number of parts in a short period of time, allowing the company to compete on both price and speed of production. It is possible to produce die castings in the shortest amount of time possible thanks to pressurized injection technology, which results in significant savings in both time and money for the end customer.

The use of a permanent mold to cast a material results in the material having the highest level of strength possible for that particular material when cast.

New Jersey, United States of America -This report on the 4x8 aluminum sheet Alloys Aerospace Materials Market includes business predictions for the years 2022-2029, as well as information on corporate strategy and the size of the industry. It then moves on to the evaluation of the competitive environment, which includes key demographics, classification, and customer performance. This market study also assists firm participants in maximizing their market presence by providing an overview of the marketplaces and market-related statistics, as detailed in the report. Aside from that, the market is segmented based on application, product category, end user, and geographical location. These critical data points will assist key players in outperforming the competition and generating enormous revenues for the organization. It also provides newcomers with specific investment options that will aid them in making profitable business decisions in the future.

Large corporations will benefit from the extensive information provided in the Aluminium Alloys Aerospace Materials market report, which will allow them to gain a thorough understanding of their customers and, as a result, achieve their goal of selling items in large quantities while also making large profits in the process. Setting a clear company goal from the beginning will assist you in avoiding problems and getting your company up and running as quickly as possible. The language used in an Aluminium Alloys Aerospace Materials market report is usually simple and straightforward in order to ensure that interactions are fruitful. The use of engaging language in the market report piques the reviewer's interest and captures his or her attention. Because of this, it has a long-lasting effect on the market's customers.

In terms of product type, application, and geography, the Aluminum Alloys Aerospace Materials market is segmented into three categories:Considering market share, compound annual growth rate (CAGR), value and volume growth, and other important factors, all of the segments of the Aluminium Alloys Aerospace Materials market are thoroughly investigated. The report also includes precise projections for the compound annual growth rate (CAGR), revenue, production, sales, and other calculations for the Aluminium Alloys Aerospace Materials market. Each regional market is thoroughly examined in the report, which helps to explain why some regions are progressing at a rapid pace while others are progressing at a slower pace. In addition, we have provided Porter's Five Forces and PESTLE analysis in order to conduct a more in-depth analysis of the Aluminium Alloys Aerospace Materials market.

Aluminum is a highly adaptable metal. aluminum supplier is used to store beverages, to construct buildings, to fly airplanes, and to propel automobiles. Because of its widespread application, industry experts anticipate that demand for painted aluminum sheets will grow at a compound annual rate of 5% through 2026. Some of the factors contributing to that forecast include a recovering global economy following the COVID-19 pandemic, as well as increased spending on infrastructure.

This forecast is encouraging for aluminum stockholders. Here's a closer look at the ways in which investors can profit from the expansion of the aluminum company industry.

Following the selection of a domain name, purchase as many extensions as you are able to afford, such as. com,. net,. org, and other variations of these domain names, as well as any other domain names that you may be interested in. Separate your posts into sections and include images to keep your reader or viewer interested in what you're saying. In order to produce high-quality content, it is not necessary to invest in expensive equipment. A $1000 camera or $500 video editing software are not required; save those expenses for when you begin to earn a living from your blog, which brings me to my next point...

If you are not interested in using your blog to generate additional income, you will eventually have to figure out a way to make human hair lace front wigs profitable. Although placing advertisements on your blog or in your videos is one method of earning money from your blog or videos, it is not the only method available to you.

AT STEP 7, GET INVOLVED IN SOCIAL ACTIVITIES.

My previous post stressed the importance of ensuring that your domain name is easily translated into social media handles, as you will be expected to do so.

STEP 8: ALWAYS BE COMPLETELY TRUE TO YOURSELF IN EVERYTHING YOU DO.

It's important to maintain your own unique voice and values when accepting and completing product evaluations. This is true whether you're reaching out to curlyme color hair lace closure wigs company companies or they reach out to you. A number of companies whose branding, ingredients, or mission did not align with my own have offered me free products in the past, and I have never hesitated to turn them down on principle. Because your readers will lose trust in you if they see you gushing over every single product that you review, it is essential that your reviews are honest.

Spectrophotometers are instruments that measure the wavelengths of light emitted by objects.

They are used by manufacturers to monitor color accuracy throughout the manufacturing process as part of a color control program, according to the company. They are used by brand owners and designers to specify and communicate color, and they are also used by brand owners and designers to communicate color. The instruments can measure almost anything, including liquids, plastics, paper, metal, and fabrics, and they can assist in ensuring that color consistency is maintained throughout the production process.

This week, we'll look at how spectrophotometers work, how they're used, and the most common types of spectrophotometers currently available on the market.

What spectrophotometers do and how they work are explained in detail.

It is possible to use spectrophotometry to measure reflected or transmitted light across the spectrum and to produce a visual curve that describes the color of a substrate when exposed to a specific lighting condition.

A white surface reflects all visible light energy across the visible spectrum, resulting in a straight line that spans approximately 90 to 100% of the visible spectrum, which is the reflectance curve of a white surface. Black absorbs almost all of the light energy that it comes into contact with, resulting in a flat reflectance curve that is close to being zero. A straight line represents a mid-range gray at 50% reflectance, which is a mid-range gray. In order to achieve a mid-range gray, equal amounts of white and black must be combined. When compared to the rest of the spectrum, other colors show a significant increase in intensity near the portion that is most reflected.

Spectrophotometers can be divided into a number of different categories.

Aspectrophotometers are generally classified into three categories, with the type of cheap spectrophotometer that is selected depending on the application and functionality that is required.

This instrument measures light reflected at a fixed angle to the sample, usually 45 degrees, and can exclude gloss in order to most closely replicate how the human eye perceives color. It is most commonly used to measure color in textiles. As well as being the most common, it is also the most accurate type of double beam spectrophotometer available. A common application for these instruments is for the purpose of measuring color on smooth or matte surfaces.

Instruments that are spherical can measure light reflected from all angles, allowing them to make measurements of color that are extremely close to those seen by the human eye. These instruments are frequently used to measure color that has been applied to textured surfaces such as fabrics or carpeting, which is a common application. Furthermore, they are employed for the measurement of color on reflective or mirror-like surfaces, such as metallic inks, printing over foil, and other highly reflective surfaces.

If you look at color through multiple angles of view, it appears as if it is being moved back and forth, much like you would twist a sample to see the color from various perspectives. Today's multi-angle instruments are used in a variety of applications, including nail polish and automotive coatings, where specially coated pigments and special effect colors containing additives such as mica and pearlescents are used to create beautiful effects.

Spectrophotometers are available in a variety of sizes, ranging from small, portable devices to large benchtop instruments, among others.

When I say that I despise blondes, it's an understatement because they deceive me into believing that everything is just so much fun, I mean it. This one is particularly disappointing because it has absolutely nothing on it, despite the fact that it has long been desired. It's true that I could even return these, but I am not going to do so. That's perfectly acceptable to me.

Nate's contract has been extended for another year. And to think that I had come up with such a brilliant concept. What was it that I believed I was thinking at the time?

If I had the chance, I would prefer to dress in the elf costume if I had the opportunity. Either the right or the left side of the couple must have a more attractive appearance. Perhaps I chose this because it looks better on the right or left partner, depending on your perspective. Does anyone know what the chests on their backs are called?

Whenever I smell this, images of oak chests stuffed with mothballs pop into my head, and that's exactly what I'm picturing when I smell this fragrance! You'll have to experiment a little in order to get a yes; there isn't a metal stage here, and I'm not entirely sure what that means.

I have no idea how you're supposed to put it in the front, because honest hair company can be difficult to style, and I'm completely stumped. The soothing cream would be nice, and I'm not sure how much these wigs are going to cost, but I'm confident they'll be in the 20s or 30s for the price range that I'm willing to pay. Some wigs are on my wish list, but I'm not sure how much they'll set me back, you know?

There are some lovely people and they can be seen in the distance, and it's located at the back of the building, which I find very appealing. According to what I know, the style and cut are the same as before.

As you may have noticed this week, some people can style your hair in a way that it used to be like this; however, they should look better on other people, which is why there are no balls in it. It doesn't appear to be flattering on me at this point in time.

What I have done appears to be a complete and utter failure on my part

In that case, please accept my request to have it returned because I anticipate that this item will be sold or that we will see what happens

A lot of the gown was constructed in layers, and I swear to you that I did not purchase a blonde hair company, I did not purchase a blonde wig, and I certainly did not purchase a darker wig company, I did not purchase a darker hair vendor wholesale, and I did not purchase a darker wig because these fibres feel fantastic, surprise

I'm not sure how to describe it, but this one appears to have that fancy green stuff on the top of its head, and this layer gives it the appearance of having a scalp on top of it

It appears more realistic if you are able to pull off these feats of strength

It appears to be a more realistic representation

In the back of the head, there is nothing unusual; there is no metal in the ears, and there is virgin hair company in this area to brush. Let's get this baby on our backs. I'm a little apprehensive about this one, but it appears to be a reasonable option for a low-cost way to complete the task. You may wonder if the other one is blonde, but I can assure you that it is not, and I don't need to check because I purchased this a few months ago, and this is the one I purchased a few months ago, and this is the petite hat, in case you were wondering. Was it intended for these to be swept to the side?

Although the color is quite lovely, it is an off-white blonde, so please let me know if you are interested. I believe it would be suitable for my skin tone because it has warm tones, which is why it appears to be off-white in color. On me, I'm not sure if it looks grey or not, but it appears to be grey on other people. According to the slow tree, despite the fact that it appears to be tacky grey in appearance, it is actually sexy grey in reality. That feels good, and she was surprised that there was no um, I think it's like, oh, these are hoovers, which she thought was odd. There is a divine vibe emanating from my floor, and I believe this is simply due to the natural order of things.

My reasoning for not cutting the fringes on these curtains, but rather pulling some of my own to help it blend in better because it looks more realistic, was confirmed when I was told that this was a popular trend. Everything else is secondary to the fact that this wig is extremely large and may feel a little unnatural at times. That is all there is to be concerned about with regards to this human hair wigs bundles. There are far too many sections on the side of the road for such a short distance at the end, giving the impression that you are only interested in seeing how far you can push yourself.

Please move quickly because if we do so now, we will be able to fit a little more brain into this situation. The fact that you have brought in an adjuster is perfectly acceptable to them; I haven't, and they don't care; I'm just double-checking to make sure.

There is, without a doubt, a scalp top, but it does not appear to be a realistic one. It is impossible to overstate the significance of density.

The extent to which the population density is high. The rest of it is fine; however, I neglected to mention that it is not excessively thick; however, you must add fringes to this section in order for it to work, which is strange because they are absent, giving the impression that the piece is fabricated.

Getting some bang on the table will be important if you're in a bad situation. I would recommend that you include wings in this piece if you want to do so in any way. I would recommend that you add wings to this piece if you want to make it more dynamic. If you want to include wings in this piece, I would recommend that you do so if possible.

Nonetheless, she is absolutely stunning, and I adore her; furthermore, she is simply so attractive that I am completely taken aback by her beauty and attractiveness.

Having the ability to compare and contrast the benefits and drawbacks of two different manufacturing processes can be one of the most effective methods of communicating the importance of selecting the most appropriate manufacturing process for a project, especially in the manufacturing industry. Comparing and contrasting the advantages and disadvantages of two different manufacturing processesTo give an example, urethane casting and plastic injection molding, both of which appear to be very similar on the surface but which can produce vastly different results depending on your requirements and expectations, even if they are carried out in the same location, are two processes that can produce vastly different results depending on your requirements and expectations, even if they are carried out in the same location. To begin, we'll talk about the differences between custom die casting and molding, and then we'll look at some of the similarities and differences between the two methods of manufacturing.

As a result, aluminum die casting and molding are processes that are very similar to one another in terms of how they are carried out in their overall operation. There is a significant difference in the fine details of manufacturing practices between the two countries, and this is especially true when it comes to the automotive industry. Using the term "plastisol injection molding," we are referring to the process of injecting plastic into mold cavities with the assistance of pressurized machinery. When comparing die casting aluminum and injection molding, it's important to remember that zinc alloy die casting supplier involves pouring material into a mold rather than injecting it under high pressure as is done in the latter process, which is why die casting defects causes and solutions is more expensive. Therefore, returning to the comparison, we see that the heated, liquefied material is allowed to cool and harden before being ejected or released from the mold or cast, depending on the situation.

Note that there are some differences between the molding and Metal Plating processes, including the materials used in each process, which should be taken into consideration. Molds for injection molding are typically made of metal materials such as hardened tool steel or aluminum alloy. Injection molding molds are also made of plastic materials such as polyethylene. Smaller quantities of aluminum and other less-hard metals are occasionally used, but only in small quantities and for applications with a low demand for them. Later in the document, this document will go into greater detail about the specifics of how this difference affects you and how you can make the most of it.

Injection molding is a process that uses a variety of materials, including PVC, ABS, and polycarbonate, among others. Urethane is an excellent example of a material that can be used to replicate the properties of these plastics while only producing small quantities of them.

A large number of cavities are contained within each injection molding tooling mold, resulting in higher quantities of product being produced from each cycle, which is important when it comes to quantities. Each cavity is contained within each injection molding tooling mold. Because of the nature of the process, only a small number of pieces (sometimes as few as one) are produced at a time in the majority of cases.

Finally, let us consider how the tooling for each process is developed and assembled. Typically, urethane casts are created by molding a 3D printed model of the finished part, whereas injection molding tools are machined to create the finished part using CNC grinding, milling, and other processes. Urethane casts are used to make molds for injection molding.

Make certain that you thoroughly brush your teeth before proceeding with the rest of the procedure.

The production process of hair closure from Honest Hair Factory

Hairstyles with straight lines should be brushed more frequently than styles with waves; however, wavy styles should not be brushed as frequently as styles with straight lines. In order to avoid washing your hands with a brush while performing this task, try to avoid doing so. Instead, we recommend combing through your hair with a wide-toothed comb, such as this or this, to achieve the same results as before. It is possible that using combs with narrow teeth on a regular basis, as opposed to combs with wide teeth, will cause hair to frizz and shed excessively, and this is something to keep in mind. Avoid combing your Wholesale 13x5 Lace Front Wigs excessively while it is on your head in order to maintain its neat and tidy appearance. For when you're on the go and need to keep your bob wig distributor in place, you can use either a wig stand or a mannequin head, depending on your preference.

In order to achieve the best results possible, start at the ends of the hair and work your way up the length of the hair to the roots. If you start at the very beginning of the page, you may end up with a jumbled mess of text. Before you begin styling your hair, spray it with a detangling spray to help with any tangles that may already be in it before you begin styling it. Following this tip, we'll go into greater detail about the different types of hair products that should be used in your hair.

Make Use of Appropriate Materials (Tips 2 and 3)

The use of products designed for biological hair on wigs or other prosthetics should go without saying, but it is nonetheless important to mention in this context. For wigs to remain in the best possible condition at all times, it is essential that they are cleaned and maintained with products that are specifically designed for wigs. For your wavy or curly mink hair wholesale to maintain its best appearance, you'll need to understand what products you should use on it and how to apply them properly. Beautimark wigs and accessories are some of the best available on the market today, in our opinion, and the most recent collection is among the best available. Exception being nylon, which should be avoided at all costs, this line of paraben-free products can be used on a wide variety of synthetic and high-density fibers without causing a reaction. If you treat human hair wigs the same way you would treat natural hair, you will notice a significant difference in appearance.

Because it is a lightweight spray that seals in moisture and keeps your wig's tresses moisturized, it is an excellent choice for everyday wear and maintenance.

When working with human hair or heat-friendly synthetics, heat tools are permitted; however, they should be avoided when working with other types of materials. Professionals in this situation highly recommend Flex-Hold Hairspray, which is fortunate in this case. Using a hairspray with a lot of hold will help to keep your style in place and prevent your curls from becoming crunchy.

a value proposition that combines three advantages into a single packageThis does not take away from the fact that Miracle Protect is marketed as a miracle product, which is exactly what it is. Through the use of this spray, which also has detangling properties, you can achieve the following benefits: protection, hydration, and detangling of your hair and scalp.

When it comes to windy days, the third consideration is how to deal with the situation in the best way.

When it comes to keeping most hairstyles looking their best, the elements, particularly the wind, can be a real pain in the rear. Take some preventative measures to keep your curls in the proper position on windy days in order to keep them looking as good as possible. A good set of weatherproof accessories can be your most effective ally in the battle against the elements, such as wind. When it's cold outside, wrapping your hair or wearing it in a cute headscarf can keep you warm while also keeping your hair out of your face on windy days. The task can also be completed with the assistance of barrettes or clips if necessary. The importance of a well-placed ponytail or braid cannot be overstated, and you should choose your style with care. It is critical that you keep both styles as loose as possible if you want your wig's waves to stay in place.

It is necessary to restore and store your personal belongings as part of the fourth step.

If you intend to store a curly for an extended period of time, you must take precautions to ensure that a curl does not fall out of the hair wholesaler while in storage. Because the procedure is straightforward in nature, it is recommended that you take your time and complete it completely. Everything else you will need to complete this task will be provided by your own hands and your imagination. This look can be achieved by sectioning off a section of hair and pinning it in place separate from the wig's hair. If you divide your hair into smaller sections, as described above, you will achieve curls that are looser but tighter. If you want to achieve loose waves, choose sections that are larger in size. After that, using your index finger, twist each curl back into its original curly pattern to complete the procedure. Every time you curl your hair, make sure to follow the instructions in this section.

Keep your wig in a cool, dark place when it's not in use so that it doesn't get too hot or uncomfortable to wear when it's out of the house. You should store items in the box they came in when they were first purchased if you want to keep them as safe as possible. It is acceptable to use another container such as a shoebox or a small plastic tote in the event that you do not have access to one of the previously mentioned containers.