ndpetrify4's blog

For the production of robust functional parts such as panels, brackets, and enclosures, sheet metal fabrication is an excellent prototyping and manufacturing technique.

Although sheet metal fabrication, in contrast to other manufacturing techniques, is actually made up of a number of different processes, each of which manipulates the sheet metal in a different way. Cutting the sheet metal, shaping it, and joining different pieces of it together are all examples of the various processes that can be used.

A look at the major sheet metal fabrication processes, as well as an explanation of their operation and application are covered in this guide.

What is sheet metal fabrication, and how does it differ from other types of fabrication?

Formalized sheet metal fabrication refers to a collection of manufacturing processes for transforming sheet metal into usable parts. This guide is organized into three categories of processes: cutting, deformation, and assembly. Cutting is the first category, followed by assembly.

Steel, stainless steel, aluminum, zinc, and copper are all common sheet metals, and these materials are typically available in gauges ranging from 0.006 to 0.25 inches (0.015 to 0.635 centimeters) thick. Steel, stainless steel, aluminum, zinc, and copper are also common sheet metals. Thinner gauges are more malleable, whereas thicker gauges may be better suited for heavy-duty parts that will be subjected to a lot of stress in their applications.

Sheet metal fabrication, particularly for partially flat or hollow parts, can be a more cost-effective alternative to processes such as casting and machining. It is also a time-saving procedure that results in minimal material waste.

In general, sheet metal fabrication is used for industrial and consumer parts, and it is also used in specialized industries such as the automotive industry, aerospace, energy, and robotics.

Fabrication of sheet metal: cutting and bending

The act of cutting sheet metal is one of the three primary methods of manipulating it. It can be considered a subtractive manufacturing process (similar to CNC machining) in this context because it allows for the creation of functional parts by simply removing sections of material from a sheet of metal.

A variety of different pieces of machinery, including some that are specifically designed for sheet metal fabrication, can be used by manufacturers to cut sheet metal.

Laser cutting is a popular method for cutting sheet metal, and it is one of the most effective. A laser cutter makes use of a powerful laser that has been magnified by a lens or mirror. A precise and energy-efficient machine suitable for thin or medium gauge sheet metal, it may struggle to penetrate the hardest of materials, such as granite or marble.

Water jet cutting is yet another method of sheet metal fabrication. Water jet cutting is a sheet metal fabrication technique that involves cutting through the metal with a high-pressure jet of water (mixed with an abrasive substance). Water jet cutters are particularly useful for cutting sheet metals with low melting points because they do not generate heat that could cause the metal to deform unnecessarily during the cutting process.

Plasma cutting is the third type of sheet metal cutting available. A plasma cutter works by creating an electrical channel of ionized gas, which then forms a jet of hot plasma that can easily penetrate even thick gauges of sheet metal, according to the manufacturer. Plasma cutters are fast and powerful machines with low setup costs, despite the fact that they are less accurate than laser or water jet cutters.

Although these three cutting machines can be used on a variety of materials other than sheet metal, there are some techniques that are specifically designed for sheet metal fabrication.

For example, the process of punching (also known as piercing) is used to create precise holes in sheet metal by using a punch and die combination. The sheet metal is sandwiched between the two components, and the punch pushes its way through the metal to reach the die at the other end. The circular pieces of removed material that are punched out during the punching process are turned into scrap, but these circular pieces can also be used to create new workpieces, which is referred to as blanking.

When creating a large number of holes, similar equipment to that used for perforating sheet metal can be used.

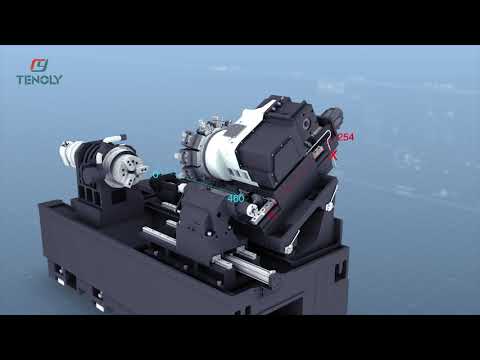

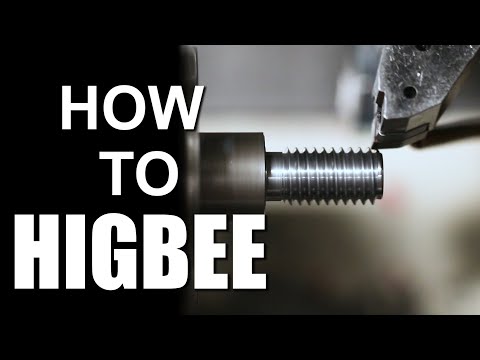

When it comes to machine tools, a lathe is one of the most efficient and effective options currently available. This material is used in the production of machine parts, furniture, and other related items, among other things. It is necessary to make several modifications to the lathe machine. The manufacturing process has been simplified as a result of this modification, and the number of applications for the lathe has increased as a result of technological advancement.

With the pressing need for progress, the development of a new technologically advanced machine known as a CNC lathe machine paved the way for further advancement. The cnc lathing is essentially a more sophisticated version of the manual lathe machine that can be used to turn metal. A computer-controlled numerical control machine (CNC) replaces the manual process by making use of a computer, which makes the process much simpler. The work can be completed in a very short period of time, and the level of precision is extremely high throughout. These are just a few of the advantages of working with a CNC machine.

Purchase of a lathe cutting tools is highly recommended if you are thinking about getting one for your business. In this article, we'll go over some of the benefits of purchasing a used manual lathe or lathe cutting tools for your shop.

Prior experience is not required as much as previously thought:Manual lathe machine operation necessitates a combination of practical knowledge and a great deal of hands-on experience. Only a small number of people are confident in their ability to operate a manual lathe machine. The beginning will be very difficult, and you may end up wasting an enormous amount of time and resources as a result of your efforts. There will be limitations on the ability to create work that is novel and innovative. In contrast, if you work in CNC, you will be able to perform a wide range of creative and complex tasks with little or no prior experience or knowledge.

Using a CNC machine, you can expect high levels of consistency and accuracy in the work that you produce. The manual lathe machine can be used, but it will require a high level of professionalism, as well as an extended period of time. It is true that the cost of a CNC machine is significantly higher than the cost of a manual lathe machine, but you will see significant returns on your investment relatively quickly.

In this day and age of technological advancement, it is always preferable to invest your money in a used cnc lathing rather than a new one.

Other products that use OLEDs include virtual reality headsets, tablet computers, laptop computers, and televisions. In addition to mobile phones and digital cameras, OLEDs can be found in a variety of other products. By 2021, more than 500 million AMOLED screens will have been manufactured, with the vast majority of these screens being used in a variety of applications, including smartphones, wearables, tablets, laptops, and televisions, among others. Samsung Display, the world's leading manufacturer of AMOLED displays, has a stranglehold on the market, and today's high-end smartphones are equipped with either rigid or flexible OLED displays, depending on the model. Apple, Samsung, Huawei, Oppo, Motorola, Sony, and other manufacturers are among those who have produced devices in this category.

There are a number of disadvantages to using OLEDs.

OLEDs are not without their drawbacks, as you can see below. Although it is currently more expensive to manufacture an OLED display modulethan it is to manufacture an LCD display, this should change in the near future, as OLEDs have the potential to be even more affordable than LCD displays in the future due to their simple design (some believe that future round lcd display displays will be printed using simple ink-jet processes, as is the case with current LCD displays).

In common with any display technology (as is true of all displays, really), OLEDs have a limited lifespan, which was a major source of concern when the technology was first introduced a few years ago. With each passing year, progress has been made, and today this is almost a non-issue when compared to what it was in previous decades. When it comes to battery life, OLEDs have improved significantly, making them suitable for use in mobile devices and televisions. It is also possible that OLEDs will malfunction if they are exposed to direct sunlight for an extended period of time due to their emmissive nature. In spite of the fact that companies are constantly working to improve it, newer AMOLED displays (including Samsung's Super AMOLED and Super AMOLED Plus displays, as well as Nokia's CBD displays) are quite good in this regard – some believe they are even better than LCDs in this respect.

small oled displaywhite lighting is a type of LED lighting that is available in a variety of colors, including white and a variety of colors.

OLEDs have the potential to be used to create a high-quality lighting source in the future. When it comes to diffuse area lighting, OLEDs are useful because they have a variety of characteristics such as being flexible and efficient while also being thin and transparent, as well as being color-tunable and having a variety of other characteristics. They are also friendly to the environment, as previously stated. Comparing organic LEDs (OLEDs) to compact fluorescent lamps (CFLs) and LED lighting devices, organic LEDs (OLEDs) enable more innovative lighting designs while also emitting more healthy light than either of these technologies.

Many companies from around the world are currently engaged in the research and development of organic LED lighting technologies, which are becoming increasingly popular. A small volume of production means that the market is still in its early stages, with extremely high prices as a result of the lack of competition. It is expected that sunlight readable lcd lighting will become more widely used in the future, though there are still numerous challenges to overcome before mass production can be scaled up to meet demand.

However, while the average householder believes that his or her tap water is pure, a typical scientist working in a laboratory will believe that it is extremely contaminated. There was a growing recognition of the need to develop technologies that could meet the purity requirements of both researchers and manufacturers.

What is the water quality standard for potable water consumption?

The use of purified water distiller is widespread throughout industry and scientific laboratories, including in medical centers and research facilities.

Water quality standards for general-purpose applications have been established by standardization bodies at both the national and international levels of organization. Other organizations use criteria that are specific to their field in order to determine eligibility.

Purified water can be classified into three categories, according to this standard:

This product is ideal for the most demanding applications, such as liquid chromatography. Quality 1 water is completely free of any organic or ionic contaminants, whether dissolved or colloidal, and is therefore ideal for use in the most demanding applications. Quality 2 water is completely free of any organic or ionic contaminants.

When it comes to inorganic, organic, and colloidal contaminants, Quality 2 is at its purest, which makes it an excellent choice for sensitive analytical applications such as atomic absorption and trace analysis.

This type of water has the following qualities: it is suitable for solution preparation and is also suitable for the majority of chemical applications.

Exactly what type of water should I use for which application?

In terms of purified water, there are four types to choose from:

In terms of resistivity, the purest water has a resistivity in the range of 1 to 50 S / cm and has the lowest purity level. In the production of bottled distiller machine, it is used as a solvent.

Cleaning glassware, feeding scrubbers, and general solution preparation are just a few of the tasks that primary grade water is used for.

When demineralized water is used, its conductivity is typically in the range of 1.0 to 0.1 S / cm, which is considered to be normal.

The preparation of standards and analytical reagents, sample dilution, the provision of biochemical devices, and the preparation of pharmaceutical solutions are just a few of the many applications for this chemical.

A high degree of purity in terms of ionic fractions, as well as low concentrations of organic compounds and microorganisms, characterize www.chinacaremedical.com intended for general use, making it ideal for drinking and cooking.

A wide range of applications for this type of water are possible, ranging from the preparation of reagents and buffer solutions to the preparation of media for cell culture and microbiological investigations. Producing this water distiller is possible through the use of a process known as double distillation or through the use of water purification systems that incorporate a variety of technologies.

In addition to other methods, ultrapure water can be obtained by polishing water that has already been prepurified, such as through demineralization, reverse osmosis, or distillation.

Ultrapure water is required for the performance of a variety of analytical techniques, including high-performance liquid chromatography, ion chromatography, and atomic absorption spectrophotometry. Tissue culture and in-vitro fertilization are two applications that necessitate the use of ultrapure, non-pyrogenic grade water, which can be obtained from a variety of sources.

The following are some of the requirements for ultrapure water:

TOC value is limited to a maximum of 10 parts per billion (ppb). TOC resistivity in millimeters of mercury (MW cm): 18.2

Bacteriological content expressed as colony-forming units per milliliter of liquid:1 1 1 1 1 1 1 1 1 1 1 1

Particle concentrations greater than 0.22 microns per milliliter are considered high.1 1 1 1 1 1 1 1 1 1 1 1

What Are the Different Types of Water Purification Methods Available?

The softener's ingredients are as follows:

It works by exchanging the Mg2+, Ca2+, and CO2-3 ions that are responsible for the formation of limestone with Na+ and CL ions. This prevents the formation of limestone and makes equipment maintenance easier by reducing the formation of limestone. Water retains its charge because this is an exchange procedure rather than a purification procedure. The process of maintaining a tank consists in providing it with salt on a consistent basis. The advantage is that the operating costs are based on the low cost of salt, which makes it a cost-effective option.

Water that has been heated to evaporation is condensed and collected by a distiller, which is also known as a collector.

If you use the water that is produced as soon as it is produced, it is free of pyrogens and sterile. Distillation is the only method of producing water for injectable products that has been approved by the Food and Drug Administration (FDA) due to the excellent quality of the distilled water machine produced. A high level of maintenance, including frequent descaling, is required in order to maintain purity and protect the heating elements. It takes 60 liters of cooling www.chinacaremedical.com to produce one liter of distilled chinacaremedical, which means that the operating costs are extremely expensive. Its advantages include being particularly well suited for one-off or low volume production.

According to the manufacturer's instructions, the osmosis unit operates as follows: water is injected under pressure into a semipermeable membrane and allowed to pass through.

In a permeate, the water passes through the membrane without accumulating pollutants, which are then discharged into the sewer system after passing through. It is guaranteed that 95 to 99% of all pollutants will be eliminated. Thus, the final conductivity is influenced by the quality of the raw water that was used in the process. The membrane also captures bacteria and pyrogens, resulting in water that has superior microbiological quality. All that is required for maintenance is the replacement of the membrane every 2-3 years and the replacement of the pre-treatment cartridge every 6 months. The advantage of using an osmosis unit is that it does not require a lot of consumables to function properly.

The demineralizer is made up of a resin made up of polymer beads that is passed through the water to remove minerals.

The anionic resin is in charge of exchanging the anions for the OH- ions in the solution. The cationic resin is used to exchange cations for the H + ion in a chemical reaction. Monitoring the saturation of the resin in order to ensure that it is replaced in a timely manner is the responsibility of the maintenance team. When the flow rate is too low, the resins are thrown away and are not recycled. They are automatically or manually regenerated by circulating soda and acid when dealing with high flow rates. The cost of operation is determined by the frequency with which the resins are replaced and, as a result, by the hardness of the water that is used in the process of regeneration. Advantage: The demineralizer's operation is extremely adaptable, and it is capable of handling a wide range of water flow rates.

In most cases, it is supplied with tap water, which is then filtered until it produces ultra-pure type I water (as defined by international standards ASTM ISO 3696 Quality 1) or pure type III water (depending on the model), as defined by international standards.

By removing any germs or microorganisms from the water supply, this laboratory equipment ensures that the quality of filtered water is maintained at the highest possible level for your daily operations in the laboratory.

However, while the average householder believes that his or her tap water is pure, a typical scientist working in a laboratory will believe that it is extremely contaminated. There was a growing recognition of the need to develop technologies that could meet the purity requirements of both researchers and manufacturers.

What is the water quality standard for potable water consumption?

The use of purified water distiller is widespread throughout industry and scientific laboratories, including in medical centers and research facilities.

Water quality standards for general-purpose applications have been established by standardization bodies at both the national and international levels of organization. Other organizations use criteria that are specific to their field in order to determine eligibility.

Purified water can be classified into three categories, according to this standard:

This product is ideal for the most demanding applications, such as liquid chromatography. Quality 1 water is completely free of any organic or ionic contaminants, whether dissolved or colloidal, and is therefore ideal for use in the most demanding applications. Quality 2 water is completely free of any organic or ionic contaminants.

When it comes to inorganic, organic, and colloidal contaminants, Quality 2 is at its purest, which makes it an excellent choice for sensitive analytical applications such as atomic absorption and trace analysis.

This type of water has the following qualities: it is suitable for solution preparation and is also suitable for the majority of chemical applications.

Exactly what type of water should I use for which application?

In terms of purified water, there are four types to choose from:

In terms of resistivity, the purest water has a resistivity in the range of 1 to 50 S / cm and has the lowest purity level. In the production of bottled distiller machine, it is used as a solvent.

Cleaning glassware, feeding scrubbers, and general solution preparation are just a few of the tasks that primary grade water is used for.

When demineralized water is used, its conductivity is typically in the range of 1.0 to 0.1 S / cm, which is considered to be normal.

The preparation of standards and analytical reagents, sample dilution, the provision of biochemical devices, and the preparation of pharmaceutical solutions are just a few of the many applications for this chemical.

A high degree of purity in terms of ionic fractions, as well as low concentrations of organic compounds and microorganisms, characterize www.chinacaremedical.com intended for general use, making it ideal for drinking and cooking.

A wide range of applications for this type of water are possible, ranging from the preparation of reagents and buffer solutions to the preparation of media for cell culture and microbiological investigations. Producing this water distiller is possible through the use of a process known as double distillation or through the use of water purification systems that incorporate a variety of technologies.

In addition to other methods, ultrapure water can be obtained by polishing water that has already been prepurified, such as through demineralization, reverse osmosis, or distillation.

Ultrapure water is required for the performance of a variety of analytical techniques, including high-performance liquid chromatography, ion chromatography, and atomic absorption spectrophotometry. Tissue culture and in-vitro fertilization are two applications that necessitate the use of ultrapure, non-pyrogenic grade water, which can be obtained from a variety of sources.

The following are some of the requirements for ultrapure water:

TOC value is limited to a maximum of 10 parts per billion (ppb). TOC resistivity in millimeters of mercury (MW cm): 18.2

Bacteriological content expressed as colony-forming units per milliliter of liquid:1 1 1 1 1 1 1 1 1 1 1 1

Particle concentrations greater than 0.22 microns per milliliter are considered high.1 1 1 1 1 1 1 1 1 1 1 1

What Are the Different Types of Water Purification Methods Available?

The softener's ingredients are as follows:

It works by exchanging the Mg2+, Ca2+, and CO2-3 ions that are responsible for the formation of limestone with Na+ and CL ions. This prevents the formation of limestone and makes equipment maintenance easier by reducing the formation of limestone. Water retains its charge because this is an exchange procedure rather than a purification procedure. The process of maintaining a tank consists in providing it with salt on a consistent basis. The advantage is that the operating costs are based on the low cost of salt, which makes it a cost-effective option.

Water that has been heated to evaporation is condensed and collected by a distiller, which is also known as a collector.

If you use the water that is produced as soon as it is produced, it is free of pyrogens and sterile. Distillation is the only method of producing water for injectable products that has been approved by the Food and Drug Administration (FDA) due to the excellent quality of the distilled water machine produced. A high level of maintenance, including frequent descaling, is required in order to maintain purity and protect the heating elements. It takes 60 liters of cooling www.chinacaremedical.com to produce one liter of distilled chinacaremedical, which means that the operating costs are extremely expensive. Its advantages include being particularly well suited for one-off or low volume production.

According to the manufacturer's instructions, the osmosis unit operates as follows: water is injected under pressure into a semipermeable membrane and allowed to pass through.

In a permeate, the water passes through the membrane without accumulating pollutants, which are then discharged into the sewer system after passing through. It is guaranteed that 95 to 99% of all pollutants will be eliminated. Thus, the final conductivity is influenced by the quality of the raw water that was used in the process. The membrane also captures bacteria and pyrogens, resulting in water that has superior microbiological quality. All that is required for maintenance is the replacement of the membrane every 2-3 years and the replacement of the pre-treatment cartridge every 6 months. The advantage of using an osmosis unit is that it does not require a lot of consumables to function properly.

The demineralizer is made up of a resin made up of polymer beads that is passed through the water to remove minerals.

The anionic resin is in charge of exchanging the anions for the OH- ions in the solution. The cationic resin is used to exchange cations for the H + ion in a chemical reaction. Monitoring the saturation of the resin in order to ensure that it is replaced in a timely manner is the responsibility of the maintenance team. When the flow rate is too low, the resins are thrown away and are not recycled. They are automatically or manually regenerated by circulating soda and acid when dealing with high flow rates. The cost of operation is determined by the frequency with which the resins are replaced and, as a result, by the hardness of the water that is used in the process of regeneration. Advantage: The demineralizer's operation is extremely adaptable, and it is capable of handling a wide range of water flow rates.

In most cases, it is supplied with tap water, which is then filtered until it produces ultra-pure type I water (as defined by international standards ASTM ISO 3696 Quality 1) or pure type III water (depending on the model), as defined by international standards.

By removing any germs or microorganisms from the water supply, this laboratory equipment ensures that the quality of filtered water is maintained at the highest possible level for your daily operations in the laboratory.

Honesthairfactory is one of the most recent additions to the online store, and it offers a diverse selection of colorful human hair wigs and pre-colored virgin human hair extensions in a variety of colors, as well as other accessories. Providing high-quality hair wigs at affordable prices, HonorableHairFactory caters to women who want to change their hairstyle on the fly and with little effort on their part.

In addition to a variety of colorful, stylish, and reasonably priced virgin human hair products, Honesthairfactory also offers Lace Wigs, Headband Wigs, Lace Frontal Wigs, and Human Hair Weave Bundles, among other things. Honesthairfactory is a company based in the United Kingdom of Great Britain.

Honesthairfactory Virgin Human Hair Products are among the most widely used in the industry, and those produced by the Honesthairfactory are among the most popular.

Lace front wigs with a hairline are available in a variety of colors.

It is available in a variety of lengths ranging from 14 to 24 inches, and it is entirely constructed of 100% virgin human hair and lace in a medium brown color. At Honesthairfactory, you will find an extensive selection of Hairline lace wigs in a wide range of styles. These include bob wigs and straight hair, as well as body wave and jerry curly styles, among many other options.

These hair bundles are made from Brazilian hair, which is a luxurious type of hair.

Instead of purchasing human hair wigs of the highest quality, Honesthairfactory also provides customers with the option to purchase Brazilian hair bundles as an alternative. Alternatively, consumers can select any combination of three to four bundles, as well as the option to close the bundles at their discretion, from which they can benefit.

Wigs with a headband are available on the marketplace.

Since its inception, Honesthairfactory has added a new line of hair care products to its product line. Additionally, a new hairstyle that is in keeping with the most recent fashion and styling trends will be provided as an added bonus. Headband wigs can save you a significant amount of time over traditional wigs because they are less difficult to put on and take off than traditional wigs.

Almost all of the products available for purchase at Honesthairfactory can be found in a variety of different color options. You can choose from a variety of sizes and a variety of colors, including classic black and exaggerated colors such as blue and pink, among others. In terms of color wigs, the Burgundy Wig, the Ginger Wig, and the Highlight Wig are the three most popular options currently available on the market. Honesthairfactory also carries colors in a variety of other shades, including ombre shades.

Fairhairfactory. com is an online store that specializes in the sale of hair extensions.

Honorhairfactory was founded on the principle of allowing every customer to be able to wear a suitable colorful wig. The company focuses on high-quality products while also offering customers 24-hour online service and being available to assist customers from the time before-sale through after-sale. Honesthairfactory is a trademark of Honest Hair Factory, which is a registered trademark. Because of their quick delivery service, they have been able to sell virgin human hair wigs and bundles to customers in a variety of countries; all orders are shipped out the same day they are received. When you purchase human hair wigs from Honesthairfactory, your order will be picked up and shipped using the most appropriate shipping method within 2 hours of receiving your payment. All orders will be processed and shipped within 24 hours of being received and will be delivered to their destination.

The Honesthairfactory has quickly gained traction since its launch earlier this year, particularly among women of color. In the opinion of the founder of Honesthairfactory, wigs offer women more than just a change in hairstyle; they also give them the opportunity to pursue their own sense of beauty and self-expression. To begin with,human hair wigsgive the wearer complete control over his or her own hairstyle and color, which is a significant advantage over synthetic alternatives.

With the mission of bringing color to life, Honesthairfactory hopes to inspire women to pursue beauty while also assisting them in discovering their own unique personal style through color. The wigs have been purchased by a number of customers in the United States, Europe, and Africa, all of whom have expressed satisfaction with their purchases. Customers have made the following observations, which we have included below:Honesthairfactory has consistently provided me with high-quality wigs at reasonable prices. The seller's communication was excellent, and the wig was delivered on time. Everything about the wig matches what was described in the description. Something like this is something I strongly encourage you to try.

We here at Honesthairfactory enjoy wearing wigs, whether they are made of synthetic or natural human hair, and we encourage our customers to do the same as well. In all honesty, we would prefer not to have the entire world know that we are constantly sporting an artificial hairstyle on our heads if we are being completely honest with ourselves about this. A group of strangers who are conversing with one another in hushed tones is a strange sight. In case you're wondering, yes, that is a curly hair you're wearing. Especially in some situations, such as standing in line at the grocery store or at the banking facility, feeling beautiful and confident can be difficult; conversely, feeling beautiful and confident when you are wearing a wig can be difficult; this is true regardless of whether or not you are wearing hairpieces to cover your bald spots or wigs. The good news is that by following the steps outlined below, you can ensure that your wig remains your best-kept secret at all times. To be clear, this does not imply that you should rush out and buy the most expensive human hair wig you can find right away. Irrefutable evidence exists that investing in an excellent-quality hairpiece can significantly enhance one's facial features. It is important to note, however, that when the wig is not properly attached and cared for, it will appear just as unnatural as, if not more so, than a low-cost synthetic costume wig purchased for less than $50.

In the first place, make it a habit to have your wig professionally cleaned and repaired on a regular basis. Using an old and musty wig to alert the rest of the world that you're wearing a wig is one of the most effective ways to draw attention to yourself. If you're going to be wearing a wig, make sure it's an old and musty version of yourself. Given that no one has yet developed a hair-regenerating wig, we'll have to make do with wigs that gradually lose their quality over time as a result of normal wear and tear. Whatever you do, no matter how hard you try, there is no way to save a freetress water wave that has passed its expiration date. There will be no amount of wig styling products or cap adjustments that will be able to save it from this state of affairs. The manufacturer's recommendations state that you should replace synthetic wigs every 3 to 6 months and human hair wigs every 6 to 12 months, depending on how frequently you wear them.

A succinct summary of the second can be summarized in two words as follows:established in a strong mannerThis situation necessitates the use of color to a significant degree. Given the fact that your hair is unlikely to be uniformly colored (unless you are born with dark hair), there is a very small chance that it will be uniformly colored. The majority of the time, people's hair is a rainbow of colors and gradients that runs through it almost the entirety of the time. To describe the gradients in your hair that are present, your stylist will use the term "dimension."As a result, when compared to wigs dyed in other colors, wigs dyed in a single flat color appear to be extremely realistic, which is attributed to their existence. If you're looking for gradients that look as natural as possible, rooted colors are the best option. Rooted colors can mimic the natural gradients found in biological hair by blending several different colors together. Unfortunately, it appears that there isn't anything in the wig market that you'd be interested in purchasing that has rooted colors in it right now. Choose a wig style that is a blend of two colors, or have your stylist apply highlights and lowlights that are two shades away from the wig's base color if that is what you prefer, rather than using highlights and lowlights that are two shades away from the wig's base color. It can clearly be seen in the photograph that Keira Knightley is sporting her signature wig of hers.

Clothing with lace trim on the front and bottoms, as well sleeves made of monofilament fabric, is ideal for the spring and summer months. When Keira Knightley revealed that she was experiencing hair loss in a public forum in 2013, it was the first time she had spoken out about it in years. Prior to this announcement, she revealed that she had been wearing wigs on set and at red carpet events for several years prior to making the announcement. None of her friends or family members were aware of her decision to go public with her hair loss issues until she did so publicly in 2013. How did she manage to keep everyone guessing about what her hairstyle was going to be for the entire day, and how did she manage to keep them guessing for the entire day? In addition to having lace fronts and monofilament tops, these are essentials for any woman's wardrobe collection. Because of the appearance of your natural hairline when you wear lace front wigs, it will appear as though your wig hair is growing directly from your head, which is not the case at all. Despite the fact that monofilament tops produce the same results as polyfilament tops, they are only visible for a portion of the total length of the wig, rather than the entire length of it. The individual hairs of a monofilament top wig are sewn into the wig by hand rather than being machine applied, which gives the wig its overall appearance rather than being machine applied. In addition, the design allows the wig hair to move freely, allowing you to part the wig in any direction you desire as a result of its flexibility.

Fourth, make the situation an absolute, complete, and total disaster by bringing it to a close.

With the phrase "too perfect," it is meant to describe something that appears to be far too good to be true on the surface. According to the previous statement, this is especially true when it comes to wigs and other hairstyles. If you notice any of these signs, it's a good indication that the item in question is a forgery, and you should avoid it at all costs. According to the latest fashion trends, wig manufacturers are still catching up with the latest fashion. While the fact that many wigs come out of the box with eerily perfect parts will not detract from the fact that your natural hair will exclaim, This isn't my natural hair! when you put them on will only serve to emphasize the fact that you are not wearing your own hair, the fact that many wigs come out of the box with eerily perfect parts will.

Take a few hair strands from the top of your new wig as soon as it is delivered to you with your tweezers to get the process started as soon as possible after you receive your new wig. It is recommended that hair be cut with baby scissors so that it appears as if it is just beginning to grow out of its sockets (as depicted in the illustration), rather than with regular scissors. In order to complete the look, select a couple of hairs to be placed on the 'wrong' side of the part in order to tie everything together. Although imperfection has never looked better than it does right now, that is saying a lot considering how much better it has never looked before. You will be able to make your wig appear more realistic if you follow the instructions in this short video.• • • • • • • • • • • • • • • • • • • •

In step 5, make sure that your wig is an appropriate fit for your face shape. According to the author's book, in order to achieve a great hairdo, it is universally agreed that a woman should wait at least two weeks after receiving a haircut for her hair to begin to grow out a little before styling it.FairIt's not uncommon for us to be a little apprehensive about getting a new haircut after our hair has had a chance to grow for a few weeks. Making an appointment with your stylist and requesting that she use a razor to cut in some layers or jagged edges to mimic a natural, grown-out look is the first step toward getting this look.

6. Take a deep breath and allow everything to fall into place on its own accord.

A natural hairline appears to be replicated admirably by lace frontal wigs on the surface, but the synthetic alternative will never be able to compete with a natural hairline on an equal playing field in terms of visual appeal. For those of you who are fortunate enough to have some naturally occurring hair, you can try blending your natural hairline with the hairline of an open-collared or lace-front wig to give yourself a more natural-looking appearance. For those who are not fortunate enough to have any naturally occurring hair, you can try blending your natural hairline with the hairline of an open-collared wig. The following are some pointers and tricks for blending your natural hairline. When wearing a lace front wig, you should:First and foremost, move your wig an inch or two further back on your head than you would normally do in order to make your natural hairline more prominent and noticeable.2nd step: Using hair extension, secure the wig completely and comfortably to your head. When you're finished, use your fingers to tease everything together after spraying a small amount of dry shampoo along the part of your wig and into your hairline with your fingers. The third step is to create a list of all of the things you want to accomplish this weekend.

In order to achieve a flawless installation, it is necessary to maintain a perfectly manicured edge throughout the duration of the entire installation process. Because you have a large number of long baby hairs on your head, it is likely that your wigs for black women will also have a large number of long baby hairs on it as a result of your hairstyle choice. One of the most important factors to consider when attempting to create the illusion of a flawless surface is how to make your own edges appear flawless, which is discussed further below. People are kept on their toes as a result of the unpredictable nature of these occurrences. If you plan to use this technique, it's important to remember that the color of your wig must be an exact match to the color of your natural hair.

Despite the fact that it appears to be a cost-effective method of saving money on labor at the time of purchase, it almost always results in a significant increase in overall costs over time. Depending on the situation, Conveyor belt costs of reactive maintenance could be anywhere from three to nine times higher than the costs of preventive maintenance. Also included in this figure are the costs of secondary equipment damage, lost production, expedited shipping, and additional employee overtime.

According to a survey conducted by Plant Engineering in 2017, organizations that implemented preventative maintenance were able to reduce equipment downtime by 69% as a result. Additionally, the fact that 66% of organizations were successful in lowering the likelihood of failure while simultaneously increasing Vertical Storage operational life of the assets deserves to be mentioned.

The use of these devices enables technicians to perform routine equipment monitoring and to identify components that are not performing properly and may need to be replaced as a result of their operation. After that, it is possible to complete these replacements during scheduled downtime, which is a very convenient option for conveyor customer. According to estimates, when comparing proactive maintenance to reactive maintenance, a cost-savings savings of between 12% and 18% can be realized while also extending the equipment's useful life by a factor of two.

If the equipment is used on a frequent enough basis, an excessively reactive approach to maintenance can reduce the equipment's lifespan by up to 60%. According to safety statistics, technicians who work on reactive projects are 28% more likely to be involved in an accident than technicians who work on proactive projects, which is a significant difference. Due to the fact that they are working under strict time constraints to get the equipment up and running again, this is the case. They are frequently forced to take risks or take shortcuts that they would not have taken otherwise if they had followed a proper plan in order to complete the work safely when confronted with these circumstances.

Having Overhead Monorail Conveyor opportunity to work closely with customers in both the local and national markets as they investigate the possibility of moving away from standard, manual picking and toward automated processes has been a wonderful learning experience. I look forward to continuing to work closely with customers in the future. If distribution centers are to be properly automated, four critical steps must be completed: evaluate motor assembly lines & conveyors situation, identify the most appropriate automation, and finally implement the automation.

These are all examples of preventive maintenance: maintenance functions recommended by the manufacturer that are carried out on a regular basis in accordance with a schedule established by the manufacturer. Some examples of preventive maintenance functions are cleaning, lubrication, adjustments, and minor repairs, all of which are performed on a regular basis. Manufacturer-recommended maintenance functions are carried out on a regular basis, in accordance with a schedule established by the manufacturer, in order to keep a machine in good working order.

It is possible that motor assembly lines & conveyors number of SKUs and the volume of orders coming into your distribution center have increased, and as a result, you are not getting the most out of your pickers as a result. If your typical order has shifted away from retail sales and toward online sales, you may be receiving more requests for smaller orders as a result. This means that if you're having trouble finding enough employees to keep up with demand and meet your service level agreements, you may be running out of time. Adapting to market changes as well as reallocating fulfillment operations to meet the needs of today's ecommerce customers are difficult challenges for businesses of all sizes, large and small, in every country around the world.

It is defined as the practice of operating a piece of equipment until it completely fails, which is also referred to as responsive maintenance in some circles. Consider Hytrol conveyor and pallet conveyor following definition, which serves as an illustration:If there is a failure, all necessary maintenance activities are completed, and as a result of this failure, the problem is resolved and can be avoided in the future. Due to the desire to save money, it is common practice for maintenance activities to be postponed until after a failure has occurred. According to industry estimates, on average, customers perform their maintenance activities in this manner, with more than 55% of customers performing their maintenance activities in this manner.

You may be considering making changes to your order fulfillment process at this point, and you may have heard about the various types of picking automation that are available to you. If this is the case, you should consult with a professional. However, the question remains as to how to get started in the first place? What would you do if the benefits of automating conveyor operations of your company were immediately apparent? Would you be willing to consider it?

FOR THE PURPOSE OF Pre-Shipment Inspection CONTROL, THE SOLAR PANEL IS INSPECTED

A number of factors, including the Covid-19 outbreak, have contributed to an increase in the demand for solar energy in recent years. This increase in demand for solar energy, also known as photovoltaic panels, has resulted in an increase in the demand for solar panel quality control inspection, which has resulted in an increase in the demand for solar panel quality control inspection. This increase in demand for solar energy has resulted in an increase in the demand for solar panel quality control inspection.

As a result of the large number of people who stayed at home or worked from home during the pandemic's peak lockdown periods, people began looking for ways to reduce their energy consumption and save money on their utility bills. As a result of the exponential advancement in solar panel technology over the last few years, the cost of solar panels has decreased significantly in recent years. Because of this, solar energy is now more accessible and affordable for the average homeowner, rather than just large corporations, as a result of the recent developments.

In several countries, solar panels are becoming increasingly popular as people become more environmentally conscious and look for alternative sources of energy. Solar panels are becoming increasingly popular all over the world as a result of this. Solar panel demand has risen as a result of an increase in government subsidies in recent years, which, combined with growing environmental awareness and a desire to find alternative sources of energy, has contributed to an increase in the demand for solar panels.

In order to keep up with demand, solar panel manufacturers are increasing their reliance on third-party inspections of solar panels.

Many people are curious about what a solar panel is and where they come from. Here are some answers to their questions.

A solar panel, also known as a photovoltaic module, is a highly engineered piece of equipment that is assembled in a mounted framework and can be installed on rooftops (as is common in North America) or on raised structures (as is common in India) to generate electricity from the sun. Solar panels are becoming increasingly popular in North America and India. Solar energy systems are becoming increasingly popular in North America and India, among other places. The electricity generated by solar panels can be fed directly into a building or structure if they are connected to it via a solar panel-to-building or structure link.

What are the most serious problems you've encountered with the quality of solar panels that you've come across thus far?

One of the most significant challenges faced by the solar panel manufacturing industry is the presence of quality defects in the final product, which can be costly. However insignificant it may appear, even the smallest imperfection in solar panels can have a significant impact on the product's working life and should therefore be avoided at all costs. The use of high-quality inspection china components in the manufacture of solar panels, as well as rigorous quality control inspections – whether conducted internally or by a third-During Production Inspection to customers, are critical to the effectiveness of the technology.

Thousands of miles across the world's oceans, the goods they contain are transported in shipping containers that are stacked high on massive cargo ships and transported in shipping containers thousands of miles across the world's oceans. It has been operating since 2010, when Paul Rathnam founded Modpools, which has been constructing innovative swimming pool structures out of discarded shipping container shells and other reclaimed building materials since 2010. The company has also built pools that are seamlessly integrated with decking and other structural elements as an alternative to pool structures that are built on rooftops or pools with windows that open into living rooms. A year and a half later, constructing innovative swimming pool structures, he officially launched the business. It was in his own backyard that he finally settled on as the most convenient location. Rathnam reasoned that he could use the time saved by converting shipping containers into office space to construct an indoor pool for his employees to enjoy while the project was in progress.