ndpetrify4's blog

Monitoring the sound level during the cutting process is another option.

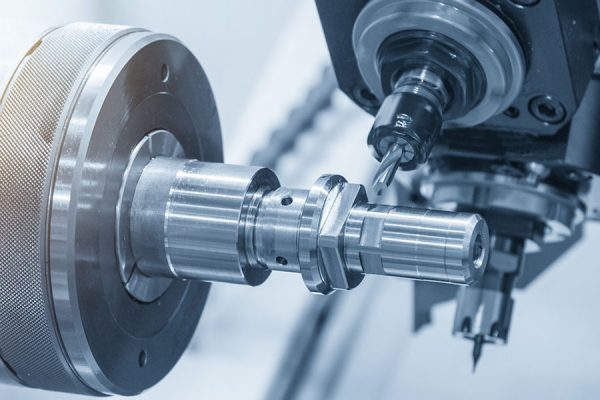

The sound produced by the tool as it cuts the workpiece is stable, continuous, and light at the outset of the cutting process in the process of automatically cutting the piece of workpiece in question. It's a good idea to double-check the motion of the machine tool right now. Hard patches on the workpiece, tool wear, or tool clamping will cause instability in the cutting process as the process moves forward. If the workpiece has hard patches, tool wear, or tool clamping, then the cutting process will become unstable. In response to the unstable performance, the cutting sound will fluctuate, a mutual impact sound between the tool and the workpiece will be heard, and the machine tool itself will vibrate. This is the period of time during which the cutting parameters and cutting conditions must be changed to ensure proper operation. When the results of an adjustment are not immediately apparent, CNC machining services China suppliers is necessary to conduct an inspection of the tools and workpieces involved.

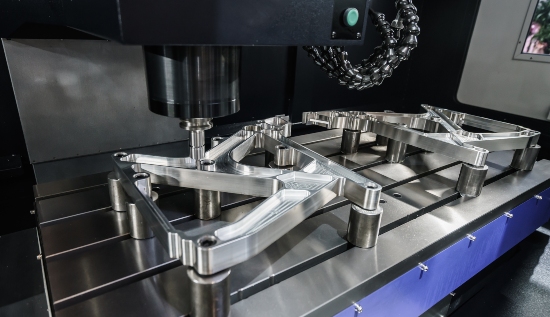

Supervision of the final machining operations after they are completed

It is planned to keep a close eye on the project's final stages until it is completed. In order to accomplish this, it is necessary to ensure that workpieces are machined to the appropriate size and quality, as well as to ensure that the cutting speed and feed rate are both high. When CNC machining services comes to chip accumulation on the machining surface, there should be a great deal of care taken. Overcutting and tool yield at the corner of the cavity are also important considerations during the cavity machining process. In order to address the issues mentioned above, you should first focus on adjusting the spraying position of cutting fluid in order to keep the machining surface cool at all times. Also important is how well a workpiece is machined, and you should make every effort to avoid quality changes by adjusting the cutting parameters to their maximum extent. If there is no apparent effect from the adjustment, immediately stop the machine and verify that the original software is still in place.

Maintain close attention to the location of the tool whenever you are suspending or terminating an examination. Consequently, if the cutting tool is forced to stop cutting as a result of the sudden spindle stop, tool marks will be left on the surface of the workpiece. Stopping the tool when it is no longer in cutting condition indicates that it is time to stop working on that particular project.

The tool's performance is being monitored.

Quality of tool monitoring has a significant impact on the quality of the finished workpiece, and the quality of the tool monitoring is critical. Through the use of various methods such as sound monitoring, cutting time control, stop inspections during the cutting process, workpiece surface analysis, and other similar techniques, automatic machining and cutting processes can be used to determine normal wear and abnormal damage conditions of the tool in use. In order to avoid problems with processing quality caused by the handling of cutting tools that are delayed, 5 Axis CNC Machining Services is necessary to handle cutting tools in a timely manner in order to meet processing demands.

junying provides a wide range of casting processes, including metal aluminum casting, rapid investment casting, permanent mold casting, rubber plaster mold die casting mould, aluminum heat treatment, and die aluminum die castings. Metal casting is one of our most popular processes, followed by rapid investment custom die casting and permanent mold die die casting services. Today, we'd like to delve a little deeper into the subject of precision sand casting, which is yet another service that our metal foundry provides to customers.

What Is Precision Sand Casting and How Does It Work?

We use "no bake sand" to produce high-quality sand castings in the shortest amount of time possible. Sand casting is the most commonly used zinc castings process, in which metal parts are formed in sand molds. It is particularly well suited for the production of more complex metal components.

What are the most common types of products that are made using sand casting?

When it comes to small and large parts, sand casting services is frequently used in the automobile industry. Pulleys, gears, and crankshafts are examples of smaller parts that are made with sand casting technology. Engine shafts and transmission cases are among the more substantial components found in a car.

When does sand casting take place and what are the stages of the process?

During the first stage, we create the mold by packing sand into each half of the mold and then removing the pattern from the mold. This results in the formation of a cavity in which the casting remains are contained. After that, we prepare the mold before it is filled with molten metal by lubricating the surface and clamping the mold halves together to prevent the mold from cracking. Following that, we pour the molten metal into the mold and allow it to cool completely before continuing. At this point, the molten metal is removed from the heat source and the excess material is trimmed off.

Do you require high-precision sand services? If sand casting is not your preferred method of metal zinc alloy die casting supplier, keep in mind that junying metal foundry employs a variety of metal casting methods, allowing us to find the services that are best suited to your prototype requirements. Aluminum, magnesium, zinc, and stainless steel are just a few of the alloys that we use in our production process.

You're probably looking for the most recent and cutting-edge women's wigs on the market. If you're looking for something particularly lovely, the Sarah Large Lace Front & Monofilament Synthetic Wig by Jon Renau is one that more than lives up to its name. With the Smart Lace (which is capitalized on purpose because it is distinctive and exclusive to Jon Renau), you never get the impression that you are wearing anything other than completely natural. Indeed, one of the most appealing aspects of the Smart Lace concept is the fact that it is so simple.What is the most effective method of locating wholesale human hair wig vendors?

Wearing a lace front wig will give you a more natural-looking hairline. Smart Lace, on the other hand, takes this to a completely new level of sophistication. Even as science progresses, there will always be a demand for human beings to perform manual labor, despite the advancements in technology. As an example, the wigs from Advancements in Wigs have a monofilament cap that can be tied with the index and middle fingers of one hand.

In spite of the fact that New Wave music first gained widespread popularity in the 1980's, the TressAllure New Wave HF Lace Front & Monofilament Top Synthetic Wig is very much of the now generation. Due to the fact that it is completely styleable, the Effortless Fiber is an important component of this. In other words, it has hair that has been cut in a professional salon. Wearing this wig all day, every day of the week, you'll feel completely comfortable and confident.

aluminium foil containerscan be used for a variety of tasks in the kitchen, including lining sheet pans, making packets for the grill, and storing food in the refrigerator. Cooking with aluminum foil, on the other hand, may have potentially hazardous consequences.

Is it a myth or a fact?

There have been numerous reports over the years that high levels of aluminum were linked to health problems such as Alzheimer's disease and kidney disease. Because aluminum can be found everywhere (including in our drinking water), it does not appear to pose a health risk when exposed on a regular basis.

Fortunately, the body has a number of mechanisms in place to assist in the removal of excessive amounts of this metal from the body. Having said that, long-term consumption of toxic levels could be harmful to the bones, brain, muscles, and other tissues of the body, including the heart.

In the Cooking Area

What should a home cook be concerned about? It could be determined by how you employ aluminum foil in your kitchen. There has not been enough research conducted to date to conclude that the use of foil will cause immediate harm.

The few studies that have been conducted have revealed that wrapping cold or cooled foods in aluminum foil for storage does not result in any aluminum leeching. However, according to a study published in 2012, cooking with aluminum at high temperatures, as well as the consumption of acidic foods, salt, and spices, resulted in a greater amount of leeching being perpetuated.

The bottom line is as follows:

More research may be required to support the decision to throw away all of your aluminum foil. Investigate whether or not the food you prepare comes into contact with aluminium foil manufacturerand whether or not this could potentially contribute to a higher than desired intake of aluminum. If you are concerned about your caloric intake, you should reserve foil for food storage rather than cooking.

The sheet tray is a true workhorse in the kitchen; it's simple to use but incredibly versatile, and it can be used for anything from roasting a chicken to baking a cake to cooking just about anything else in the oven. Making the right choice when lining a sheet tray or any other baking dish will ensure that you get the most out of your baking dish or sheet tray. And that critical decision begs the question of when, exactly, you should use aluminum foil, parchment paper, or a silicone baking mat in the first place. Each aids in making cleanup easier, preventing sticking to the pan, reducing the need for additional fat, and extending the lifespan of your pan; however, there are significant differences between them and when they should be used in conjunction with one another.

Alcoa foil is exactly what it sounds like: a very thin sheet of aluminum that can be cut and shaped. This versatile ingredient can be pressed into hard-to-reach corners (brownie pans, anyone?) and shaped into packets with relative ease. However, keep in mind that standard aluminium foil supplieris not nonstick, and stickier items may come away with small pieces of aluminum foil stuck to them after cooking.

When Should aluminium foil manufacturerBe Employed?

If you're cooking sticky or delicate foods like marshmallows or fish, non-stick foil is a good option to consider. Remember to always cook your food on the dull, non-stick side of the skillet. One of the most significant advantages of using over parchment or silicone baking mats is that it can withstand higher temperatures than these alternatives, allowing it to be used under the broiler or on the grill. It is also insulating and non-permeable, which allows it to be used to contain steam when formed into a packet (for gentle, moist cooking) or to cover a pan to protect it from direct heat when used as a lid. It can also be recycled; just make sure to wash off any food that has become stuck to it before doing so.

Medicine cabinets are available in a variety of sizes, shapes, and designs. Select a cabinet that is complementary to your sink and vanity setup.

It is preferable to have rectangular medicine cabinets installed with the long sides facing up, as this allows you to see your head, neck, and shoulders more clearly.

Traditional oval medicine cabinets open up to reveal a square frame and provide the same amount of storage space as their rectangular counterparts. These are a fun way to add a little more personality to your bathroom decor.

Arched medicine cabinets are similar in appearance to rectangular medicine cabinets, with the exception that the top and/or bottom arches to provide a rounded appearance. These may have two or three levels of storage shelves for toiletries and other bathroom necessities.

Medicine Cabinet Dimensions and Mounting Options

When plumbing or electrical wires are located inside the wall, surface-mounted cabinets should be used instead of built-in cabinets. It is simple to set up. There are a variety of sizes available. It is possible to create a decorative focal point. The process of installing a surface-mounted medicine cabinet is relatively straightforward.

Because they are built into the wall, recessed cabinets maximize available space. They take up less physical space than other options. Give the appearance of being built in. It frequently has deeper shelves. Installing recessed units can be a little more difficult due to the possibility of plumbing and electrical issues during the process. Before you begin, double-check that you have all of the necessary tools. If you're installing lights, you'll need electrical tape, cable, and wire connectors to complete the task.

Some models are labeled as having a dual mounting system. This means that they are completely interchangeable. Depending on your bathroom configuration, you can install them on a surface mount or a recessed mounting system.

The width and height of your sink or vanity should be considered when selecting the appropriate medicine cabinet size.

Medicine cabinets that measure 15 by 24 inches are ideal for sinks and vanities that are 18 to 24 inches in width.

A medicine cabinet with dimensions of 20 x 24 inches is a good fit for vanities that are 30 to 36 inches wide.

A medicine cabinet measuring 30 by 24 inches is a good fit for mid-size vanities measuring 42 to 48 inches in width.

Choose two smaller medicine cabinets to go above the faucets for larger vanities that are approximately 60 inches wide and have a double sink configuration. The size of 20 x 24 inches is a good fit for both of them.

Consider the following characteristics:

If you have children in your home, look for cabinets that have locks to prevent access to potentially harmful substances.

Mirror cleaning is reduced when cabinet doors that open with the push of a button are used instead of traditional hinges.

Mirror defoggers: Units that include magnifying mirrors make grooming more convenient. Premium cabinets may come equipped with built-in defoggers to keep the mirrors from becoming fogged up while you're in the bath or shower.

Integrated outlets allow you to charge your cell phone while you are getting ready for work, as well as plug in your electric razor, curling iron, and other small appliances while you are getting ready.

Integrated interior lighting: Having lights built into the cabinet makes it much easier to quickly see and locate what you're looking for.

Corner cabinets: If you have a limited amount of wall space in your bathroom, corner cabinets are a great option.

Reversible doors: Medicine cabinets with reversible doors have the advantage of being able to be installed for either a left or right opening. This is particularly useful if you only have a small amount of wall space above your sink.

No matter whether you're looking for a contemporary medicine cabinet or a traditional medicine cabinet, there's a shape, style, and finish that will meet your specific requirements. Find out more about our bathroom installation services, including custom shower doors and tub installations, if you're interested in more bath renovations and upgrades.

In the casting industry, investing in casting refers to the process of putting money into investments, which is defined as follows:

Investment casting, also known as lost wax casting, is a sophisticated metal forming process that can be used to create both solid pieces and hollow cores from metal. It can be used to create both solid pieces and hollow cores from metal. It can be used to create both solid pieces and hollow cores out of metal, depending on the application. Depending on the application, it can be used to fabricate both solid pieces and hollow cores out of metallic materials. Our disposable templates are used to manufacture high-quality metal components that can be thrown away after they have been used.

It is possible to create a pattern by injecting wax into a metal die, which is done with the help of a special tool. In fact, this pattern is a carbon copy of the final section of the project's final section, down to the smallest detail. In order to harden the surface and hollow them out for use in other applications, the castings are waxed and then fired at a high temperature after the ceramic has been applied. The mixture is then poured into the hot cast exterior shell of the mold, which is then finished in the following step to complete the mold construction process. Before disposing of the metal, it is necessary to blast away each and every piece of ceramic that has adhered to it. Material evaluation can be accomplished through a variety of techniques, including chemical, physical, and nondestructive testing (NDT).

During the process of casting services, a mold is filled with sand, which is then poured into the mold to produce a finished piece of metal.

Those interested in mold-making should be aware that sand casting is a technique that involves using finely ground spherical grains that are tightly packed together on a smooth molding surface to create a mold for a variety of materials. When it comes to producing both large and small pieces of artwork, it is a low-cost method of production.

Machine casting pieces in conjunction with a sand core box should be considered, as should sand core boxes and wooden or metal patterns in addition to the machine casting pieces. Pouring the component into a sand mold is the first step in the molding process. Pouring the component is the term used to describe this process. After the metal has cooled, it is blasted or otherwise surface treated in order to remove any remaining imperfections and bring the machining procedure to a successful conclusion.

Die casting is the process of pressing a solid piece of metal through a die to form a solid piece of metal. Die casting is one of the most common types of metal casting and is used in a variety of applications.

A variety of die casting processes are available to customers in the metal die casting industry. These processes include cold chamber die casting, hot chamber die casting, and multi-slide hot chamber casting, to name a few. Hot chamber die casting is a technique that is commonly used in the large-scale production of magnesium, zinc, and other low-melting-point alloys, as well as other metals. The use of cold chamber die casting is a viable and increasingly popular alternative for metals with high melting points, such as aluminum and magnesium.

Die casting is made possible by the use of metal alloys such as aluminum, zinc, and magnesium, each of which has its own set of characteristics. Die casting is made possible by the use of metal alloys such as aluminum, zinc, and magnesium. These materials provide a significant amount of shielding protection against EMI/RFI radiation when it comes to shielding protection.

Die casting services have a number of advantages, the most notable of which is that they enable the creation of complex shapes such as external threads, which would otherwise be impossible to achieve using other methods. Die casting services are available in a variety of sizes and shapes. Aside from being more cost effective, die casting services are also less expensive than other methods. Two of the advantages that can be obtained as a result of this are the reduction of secondary operations and the reduction of production costs. Die casting offers a number of additional benefits, the most notable of which are as follows:

The reduction in the number of steps between raw materials and finished goods results in a significant increase in the production speed of finished goods.

This has had a significant impact on the price of scrap metal, which has fallen significantly.

It is necessary to have extremely tight tolerances in order to function properly.

The wall thicknesses can be customized to meet your requirements.

Because of this, the surface finish and stability of the product are improved, and the product's lifespan is lengthened as a result.

The process of mold casting is accomplished through the use of a permanently installed mold.

In the process of making permanent molds for metal casting, permanent or reusable molds are created by milling mold cavities into metal die blocks and then modifying them so that they can be re-used multiple times. It is necessary to use these molds in order to shape liquid casting metals into the desired part or component of the final product.

In order to ensure that the overall dimensional stability of the product is maintained, mold casting services for permanent molds are utilized. The finished casting is much closer to its final specification than the raw casting services so the machining tolerances for finished castings are smaller than those for raw castings as a means of compensating for this. Due to the higher density and tightness of the castings produced by this process compared to those produced by other methods, the amount of finishing and surface treatment required is reduced, resulting in savings in terms of both time and money, as well as increased productivity.

Using plaster as the primary casting material is a type of casting in which the plaster material is used as the casting material itself.

It is possible to create objects out of plaster using a technique called plaster casting, which is similar to sand casting. It is possible to make a concrete substitute out of water, calcium carbonate, and a strengthening additive in order to give the concrete more strength when sand is not available. Abbott Interfast has gained the trust of numerous well-known and respected corporations in the aerospace and appliance industries, as well as the consumer goods and telecommunications industries, as a result of this. If you require any additional information, please do not hesitate to contact us.

It is possible to work in several different casting industries, each with its own set of applications.

It is extremely adaptable and can be found in a wide range of industries, including the automotive industry, demonstrating its versatility.

Electronics destined for use in the medical and automotive industries, among other applications

WMDs (weapons of mass destruction) are a type of nuclear weapon that can kill millions of people.

Electronic communications equipment is utilized in the industrial market.

Throughout history, numerous great artists have painted on a variety of unusual surfaces, including a variety of unusual surfaces, as well as a variety of unusual surfaces, as well as a variety of unusual surfaces, as well as a variety of unusual surfaces, as well as a variety of unusual surfaces, as well as a variety of unusual surfaces, as well as a variety of unusual surfaces, as well as a variety of unusual surfaces, as well as a variety of unusual surfaces, as well as a variety of unusualNatural materials such as stone, wood, and glass, rather than more traditional media such as canvas or paper, were used to create the artworks. The artists opted to work with natural materials such as stone, wood, and glass rather than more traditional media such as canvas or other types of paper in order to express themselves more fully. Please consider the following examples to gain a better understanding of what this means in your everyday life.

Because it is manufactured with an ultra matte finish on both sides, it appears to be frosted on both sides when viewed from different angles. This is accomplished by applying an ultra matte finish to both sides of the panel, giving the panel the appearance of being frosted in appearance. To achieve the desired frosted appearance on both sides of the panel, freighted Plexiglass is manufactured with an ultra matte finish on both sides of the panel, which is important to remember. Because of the ultra matte finish on both sides of the panel, it can be used to create the appearance of frosted glass on both sides of the panel when viewed from different angles. Acrylic paint that is applied to both sides uses of acrylic plastic while it is drying will adhere to both sides of the sheet and form a strong bond between the two pieces of acrylic paint that are applied to both sides of the sheet. This flexibility in terms of adjusting the clamps makes it possible to make certain that the Plexiglas is in the proper position for your specific project.

Using a specialized cleaner such as Novus #1 to thoroughly clean the surface is recommended before painting over an acrylic surface. Alternatively, thoroughly cleaning the surface with water and dish soap is recommended before beginning to paint over an acrylic surface. It is non-toxic and does not cause any pollution to the environment in any manner. No toxins are released into the environment, and it does not pollute the environment in any way. There are no toxins released into the environment, and the environment is not polluted in any way as a result of this process. Aside from the fact that no toxins have been released into the environment, there has been no pollution of the environment as a result of this process.

Acrylic painting techniques, suggestions, and tips to help you have a successful painting session are covered in this article: learn how to create beautiful paintings using acrylic paint.

Please let me know if you require any additional assistance before we begin. Thank you for your understanding. Thanks for taking the time to read this. Thank you for reading this and taking the time to do so. Thank you for taking the time to read this and for your consideration. Thank you for taking the time to read this and for taking the time to consider my request. I appreciate your consideration.

Many different variables must be taken into consideration. Access to the market and distribution are most advantageous to brands that have a distinct and differentiated point of view, and these brands reap the greatest rewards as a result of their efforts. Businesses must take advantage of every opportunity that presents itself to them in order to establish themselves as having a truly distinctive appearance that presents itself in their market niches over time. The most effective way to accomplish this is through the use of Wholesale Packaging Boxes that have been personalized. With the current economic climate, it is impossible to overestimate the profitability of these boxes. Companies can draw the attention of their target market to their products by placing them in these boxes. There is a direct relationship between the amount of attention paid to a brand's sales efforts and how successful the brand's sales efforts have been.

By checking these boxes, brands can influence the competitive landscape in which their businesses compete as a result of their actions. This strategy is being promoted by brands in order to increase sales and generate more interest among customers. Because of the use of these boxes, it is possible for us to accomplish this. Individuals in positions of authority have a significant impact on the overall outlook for the country. This transformation also results in the brands involved having a completely different and more appealing appearance and feel as a result of the transformation. Both product marketing and brand marketing are improved as a result of this procedure, which has a positive impact on both.

Low-cost custom wholesale boxes offer a significant advantage over other alternatives in terms of functionality and cost.

Uncontestable evidence exists that the services and attention provided by these boxes are of the highest possible caliber, and this documentation is readily available. Because of the way they appear, these boxes have an impact on the overall design of the page. Because of the shift in perspective, how a product is perceived in the marketplace can change as a result of the shift in perspective. This type of packaging gives products a more finished and professional appearance, which in turn encourages buyers to treat the product with greater respect as a result of the improved presentation. A significant amount of money could be made from the sale of these boxes.

If you want to be considered for this promotion, your Customized Boxes with Logo must have your company's logo prominently displayed on the outside of the container.

If an organization is concerned with increasing sales and marketing, having the capability of printing its logo on packaging boxes can be extremely beneficial to its overall health and success. This is especially true if the organization is concerned with increasing sales and marketing. Companies stand to gain significantly as a result of this development. It is necessary to position Customized Boxes with Logo in such a way that the logo is as large and impressive as possible before placing them on the product in order for them to be effective when placed on the product. Having a sophisticated and contemporary design, as well as strategically placed boxes, are required in order to make effective use of this feature.

When it comes to maintaining a competitive edge while also playing safely, the use of cigarette wholesale boxes can be extremely beneficial.

If you look at the current state of product quality, many of the brands currently available on the market are doing an excellent job in this area. Since the time the products and brands in question were first introduced to the market, there has never been any question about their superiority in terms of quality. Taking all of these considerations into consideration is critical. The way a person approaches their life is even more important than their physical health, and this is something that should not be overlooked. In an ideal world, brands would avoid engaging in this practice at all costs. Unfortunately, this is not the case. Purchase of Wholesale Packaging Boxes, to be more specific, can be extremely beneficial in this situation. A large number of years are almost certain to pass before these storage containers are decommissioned. These individuals wield a significant amount of authority in their respective roles.

In addition to providing brands with a professional appearance, these boxes also enable them to maintain their position in the face of constantly changing marketing fashions and trends, which is essential for remaining competitive. The fact that they are inconsequential details in the grand scheme of things does not diminish their importance. It has an impact on everyone and everything, and the outlook reflects how much of an impact it has had. By making use of these boxes, which are particularly important in a market that is constantly changing and where trends are everything, we can instill confidence in our product and ensure that it remains extremely simple and cost-effective in the marketplace. The level of competition that exists between businesses is one of the aspects that are taken into consideration.

Detailed instructions on how to make proper use of cigarette wholesale boxes can be found on the following page.

In order to complete the implementation of these innovative and creative boxes, it will take a significant amount of time and effort. The considerations that must be taken into account when brands compete for placement in these boxes are numerous and complicated to explain. In some cases, these tasks are required to be completed, whereas in others, it is highly recommended that they be skipped or avoided entirely, depending on the circumstances. In this context, it is critical to use contemporary and fashionable fonts, for example. This means that they must make a concerted effort to stay abreast of the most recent technological advancements. An analogous statement can be made about the natural game of colors and contrasts that takes place in the world around us every day. When it comes to choosing colors for their products, brands must exercise caution in order to be considered cool and appropriate. The designers' insufficient color selection has resulted in a reduction in the overall coolness of the product as a result of their efforts.

Aluminized products are made by heating aluminum until it becomes liquid, then pouring the liquid into a mold to form the desired shape. Because alloy steel is more corrosion resistant than aluminum and has a lower freezing point than steel, it is typically used in the mold's construction because it is more corrosion resistant than aluminum. Alloy steel is more corrosion resistant than aluminum and has a lower freezing point than steel. The use of sand as a mold material for aluminum casting is another common practice. Sand can be found in a variety of places and is relatively inexpensive to purchase. By pressing the sand into the desired shape, the sand is transformed into the desired shape. It is then necessary to incorporate the liquid aluminum into the mixture, which must then be allowed to cool completely before the process can proceed.

Alumina layer forms quickly on the surface of aluminum castings after they are cast, acting as a corrosion-resistant barrier between the aluminum castings and their surrounding environment.

Both ingot casting and mold casting are terms that are used to describe the processes that are used to create aluminum alloys. Ingot casting is a term that is used to describe the processes that are used to create aluminum alloys. When it comes to creating aluminum alloys, the term "ingot casting" is used to describe the processes that are employed. Many different techniques are available for joining the sand molds together, but the two most common are described in greater detail below.

When making green sand, a combination of sand, clay, and moisture is used, and this particular type of sand is known as green sand because of its green color.

It is used in the production of dry sand (a type of concrete), which is made up of finely ground sand and synthetic binders that have been thermally or chemically cured before being placed in the ground.

For the purpose of fabricating hollow parts of castings that will be used to fill in the gaps between the overall shape of the casting and the hollow parts of the casting, it is necessary to use a mold in conjunction with dry sand components and a mold.

When it comes to high-volume manufacturing environments, this highly adaptable technique is the one that is most frequently employed. A wide range of materials, including metals, ceramics, polymers, and composites, are created using the Dolin Casting process, which includes the following:Aluminum Sand Casting Techniques and Methods: There are a variety of options.

Such molds are typically filled with molten metal through a filling system, which allows for a more consistent filling system. When the low pressure sand casting technique is used to cast the part, a small temperature difference between the two parts of the mold is created, and the molten metal is forced into the mold as a result of the temperature difference. In addition to traditional die casting processes, such as vacuum die casting and squeeze casting, a growing number of new die casting processes are emerging, with the importance of contributions from vacuum die casting and squeeze casting processes increasing over time. The aluminum casting process that is most appropriate for your requirements should be chosen.

A specialty of Dolin Casting is the production of castings for a variety of applications. The company specializes in both sand casting and permanent mold castings. Each factor will be considered, and the best process will be selected based on how well it meets the requirement. a.

The automated sand casting technologies used by Dolin Casting Manufacturing are superior to those used by permanent mold operations because they can produce a large number of parts in a short period of time, allowing the company to compete on both price and speed of production. It is possible to produce die castings in the shortest amount of time possible thanks to pressurized injection technology, which results in significant savings in both time and money for the end customer.

The use of a permanent mold to cast a material results in the material having the highest level of strength possible for that particular material when cast.

New Jersey, United States of America -This report on the 4x8 aluminum sheet Alloys Aerospace Materials Market includes business predictions for the years 2022-2029, as well as information on corporate strategy and the size of the industry. It then moves on to the evaluation of the competitive environment, which includes key demographics, classification, and customer performance. This market study also assists firm participants in maximizing their market presence by providing an overview of the marketplaces and market-related statistics, as detailed in the report. Aside from that, the market is segmented based on application, product category, end user, and geographical location. These critical data points will assist key players in outperforming the competition and generating enormous revenues for the organization. It also provides newcomers with specific investment options that will aid them in making profitable business decisions in the future.

Large corporations will benefit from the extensive information provided in the Aluminium Alloys Aerospace Materials market report, which will allow them to gain a thorough understanding of their customers and, as a result, achieve their goal of selling items in large quantities while also making large profits in the process. Setting a clear company goal from the beginning will assist you in avoiding problems and getting your company up and running as quickly as possible. The language used in an Aluminium Alloys Aerospace Materials market report is usually simple and straightforward in order to ensure that interactions are fruitful. The use of engaging language in the market report piques the reviewer's interest and captures his or her attention. Because of this, it has a long-lasting effect on the market's customers.

In terms of product type, application, and geography, the Aluminum Alloys Aerospace Materials market is segmented into three categories:Considering market share, compound annual growth rate (CAGR), value and volume growth, and other important factors, all of the segments of the Aluminium Alloys Aerospace Materials market are thoroughly investigated. The report also includes precise projections for the compound annual growth rate (CAGR), revenue, production, sales, and other calculations for the Aluminium Alloys Aerospace Materials market. Each regional market is thoroughly examined in the report, which helps to explain why some regions are progressing at a rapid pace while others are progressing at a slower pace. In addition, we have provided Porter's Five Forces and PESTLE analysis in order to conduct a more in-depth analysis of the Aluminium Alloys Aerospace Materials market.

Aluminum is a highly adaptable metal. aluminum supplier is used to store beverages, to construct buildings, to fly airplanes, and to propel automobiles. Because of its widespread application, industry experts anticipate that demand for painted aluminum sheets will grow at a compound annual rate of 5% through 2026. Some of the factors contributing to that forecast include a recovering global economy following the COVID-19 pandemic, as well as increased spending on infrastructure.

This forecast is encouraging for aluminum stockholders. Here's a closer look at the ways in which investors can profit from the expansion of the aluminum company industry.