evoortsolutions's blog

In 2023, a total of 41.76 billion IoT or Internet of

Things-connected devices are anticipated to be deployed, per ReportLinker. As

per Guidehouse Insights’ estimations, The global market for IoT in

manufacturing is set to grow to $23.1 billion by 2031, growing at a compound

annual growth rate (CAGR) of 15.0%. Industry 4.0 is here, set to boost

competitiveness across companies.

A McKinsey research reveals IoT is poised to deliver $1.3

trillion in economic value to the manufacturing sector. Among these also is

standardized production settings, but requiring scale for ensuring thorough

capture.

McKinsey research also states IoT’s potential global

economic value to unlock by 2030 could be $5.5 trillion to $12.6 trillion. But

barriers exist, in the form of machinery upgrade costs, investment optimality,

and cybersecurity

risks.

The ultimate Industrial Internet of Things or IIoT

applicability lies in the manufacturing sector. Production lines and industrial

machines’ productivity could massively boost with internet connectivity and

sensors, monitoring production. These could include monitoring temperature,

humidity, noise, or vibrations.

Let’s examine the various IIoT trends in manufacturing:

Transforming IoT Business Model

Industrial IoT Solutions are appealing as they enhance

factory performance via augmented output, whilst also bettering key business

metrics. IoT is an automation catalyst, allowing manufacturers to transform

business models with innovation. The approaches on which IoT works include

the product, the supply chain, and the manufacturing. Championing these three

aspects would enable charting a crystal-clear smart IoT adoption strategy.

Predictive Maintenance & Performance Tracking

Big enterprises have heavily invested in their IoT and IIoT

infrastructures in 2022. In 2023, much attention would be directed toward

predictive maintenance and performance tracking in products and plants.

In today’s advanced industrial environment, factories are

even looking forward to lights-out manufacturing (total automation). IIoT

solutions and deep analytics software today can enable end-to-end production

processes’ performance tracking by manufacturers. Novel machine learning (ML)

technologies have facilitated predictive performance tracking capabilities via

sensor-collected big data analyses.

ML can also facilitate performance tracking to get better

with time, enabling industries to operate for sustained periods without human

oversight.

Equipment downtimes in production environments result in

out-of-the-blue delays and subsequent losses. So, smart operational schedules

are a must for efficient execution and asset availability. That’s when

predictive maintenance can considerably decrease machine failures and power

outages, boosting overall asset life.

Use predictive maintenance to enhance asset life-cycle,

reduce maintenance costs and time, and decrease machine breakdown to enhance

equipment monetization It also allows a reduction in accidental malfunction to

strengthen workers’ physical safety.

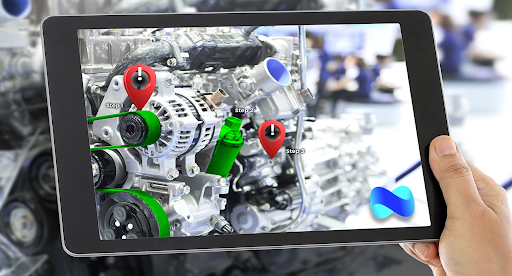

Augmented Reality (AR) and Virtual Reality (VR)

AR (Augmented Reality) and VR (Virtual Reality) can be

accessed to experience immersive training, remote

assistance, and collaboration. Instruction manuals’ digitization via AR and

VR is the next frontier in redefining industrial technologies.

Capitalizing on the prospects presented by data exploration,

Virtual and Augmented Reality can minimize waste in industrial processes. VR

and AR can be easily integrated with IoT. Together these technologies can reap

tremendous benefits. Such breakthroughs can come in the form of higher profits,

exploring fresh growth avenues via new products or services, decreased costs,

etc.

AR acts as an enhancement of the user’s surroundings via the

addition of digital components in a live environment. VR replaces real-life

environments with simulated ones as the user is completely immersed in a digital

environment. In the manufacturing sector, VR and AR can be leveraged to make

available designs, organize manufacturing lines, sharpen ideas, and remote

machinery interaction. If in the building process either of the steps is

omitted, its identification is possible via AR and VR.

AR and VR can be integrated in these ways with IoT:

Asset Management: Equipment know-how, performance, and health

data are collected via IoT sensors to transform these into their virtual form.

By doing so, real-time visualization of breakdowns and crashes is possible.

Space Management: The AR technology optimizes inventories in

factories or warehouses, developing optimal routes for workers to navigate

across facilities.

Employee Training: AR allows manufacturers to develop

virtual prototypes of products for integration with IoT data. By doing so, it

can develop a simulation wherein your employees can learn machines’ optimal

usage.

AR and VR can guide technical work by offering real-time

instructions. These technologies can also facilitate technical support on a

remote basis, making training experiences real. AR can analyze machine

environments’ problems. Computer vision in AR can give a map of machines,

allowing highly-skilled laborers to witness real-time manufacturing processes’

stats.

Big Data Insights to Boost Optimization

IoT technology essentially collects data. Industrial Big

Data, for that matter, is a central aspect of Industry 4.0. A smart factory

operates at its optimal level owing to an accurate collection and the finest

analyses of data. There are also several challenges presented by Big data, such

as the efficient collection of the required data (via IoT analytics) and

attributing to it enough value (via integrating artificial intelligence). The

availability of Big Data can make available deeper insights. Unlike traditional

technologies, a multitude of production or supply chain aspects can be tracked

via IoT devices. So, IoT is crucial from the Big Data and manufacturing

perspective.

Edge Computing

The edge computing trend is eagerly looked forward to by the

manufacturing industry as an enabler of automation implementation in factories

and supply chain processes. Edge computing can enhance manufacturing processes

via advanced robotics and machine-to-machine communication. Edge computing

essentially involves various networks and devices surrounding the user to

process data as near to its area of generation as possible at high speeds and

volumes. The outcome of this is a result-oriented action plan in real-time. In

manufacturing, via edge computing, several local edge network factory devices

can enable processing with no need to send data (to a local server first). Edge

computing is speedy, highly efficient, and indeed secure.

There is no need in edge computing for the sensitive

manufacturing data to leave (for distant server processing) the factory

premises. So, there is a reduced risk of hiccups or third-party intrusion.

Enterprises of today can boost their business prospects via the integration of

edge computing and AI, to develop Edge AI.

This way, edge computing facilitates undertaking AI

computation close to the user at the onset of the IoT network, instead of on a

cloud. So, enterprises can attain real-time intelligence in industrial

operations, strengthen privacy and cybersecurity, contain costs, and better

manufacturing processes.

Conclusion

Manufacturing industry solutions based on IIoT are poised

for stupendous growth with efficient asset

management and monitoring, predictive maintenance for reduced machine

breakdown (via performance tracking), and boosted workplace safety.

Entrepreneurs can look forward to profitable business with IIoT transforming

business models.

Industrial IoT offers an avenue to manufacturers for

leveraging emerging technologies for a smarter and speedier production

environment. Manufacturers, today, are integrating solutions that facilitate

the automation of business operations by leveraging advanced technologies to

enable innovation.

The future of enterprises is digital. Transformation is the way forward for manufacturing. A smarter, speedier, seamless, and safer production environment is next. Digital transformation is paving the hyper-automation pathway for improving efficiency.

Advanced wireless networks are set to be used to reduce downtime as the Industrial IoT (Internet of Things) gets deployed everywhere. As the production landscape is in a constant state of evolution, it’s vital to clearly decipher what digital transformation actually means.

Digital transformation primarily integrates digital technology across various areas of a business. The objective is to considerably alter the manner of operation, for delivering value to customers. Digital transformation digitizes non-digital services, operations, and products. The underlying intention is to elevate value via invention, innovation, and efficiency.

Factories and processing plants globally are embracing automation for enhanced production, efficiency, and quality.

But the future automation platforms would offer vital smart insights for real-time operational efficiency. These timely recommendations might include, for instance, machine learning-powered automation in decision-making.

Industrial Internet of Things (IIoT) technologies, cloud and edge software, machine learning (ML), artificial intelligence (AI), and low-code platforms are poised to facilitate advanced automation. Together such an apparatus would enable companies to march towards reaping the advantages of implementing artificial intelligence of things (AIoT).

With manufacturing entering the digital phase, a stark momentum is apparent in customer expectations and technological advancements.

Companies can expect to boost efficiency, use data optimally, make innovation conducive, and control cost with digital transformation. What are the buzzing trends in digitally transforming the manufacturing sector? Let’s examine the 5 (manufacturing) digital transformation trends in 2023.

- Industrial IoT

IIoT is a futuristic system to keep your business’ manufacturing lifecycle up and ready. Industrial IoT transforms processes for improving efficiency, whilst meeting the Industry 4.0 standards. In IIoT, smart sensors tend to enhance manufacturing operations. In an IIoT setting, Informed business decisions are swiftly reached at, courtesy of the intelligent devices and real-time analytics.

The idea is to boost internal processes’ cost-efficiency, whilst providing increased value to customers. An IIoT solution works in tandem with cloud computing and AI-based technology stack for robust manufacturing.

The utilization of such smartly connected devices can be done in the fields and factories, or at remote facilities. Look forward to automating core factory operations via applying IIoT solutions to deploy digital transformation. It tends to solve such pressing challenges as productivity, asset utilization, quality, and process automation.

An IIoT network of servers and devices tends to manage manufacturing and machinery lifecycles. It also collects, stores, and analyzes the data from the sensors, executes commands given remotely, develops smart alerts rules. Based on these, smart and actionable insights are prepared to streamline industrial systems, efficiency, and predictive maintenance. Refer to the generated trends monitoring and historical analysis reports, for predictive maintenance.

- Predictive Maintenance

Predictive maintenance is a prominent Industrial IoT trend, given its benefitting potential for the manufacturing sector. Predictive maintenance based on IIoT tends to utilize real-time data that analyzes the assets’ condition on an ongoing basis.

The benefits of predictive maintenance are an increased asset lifecycle, reduced maintenance costs, increased time efficiency, reduced machine breakdown boosting equipment ROI, a drop in unexpected malfunctions leading to better workers’ safety.

IIoT data lets companies use analytics tools to access insights. With it, companies use data visualization to assess the ongoing and predict the future performance challenges.

- Artificial Intelligence and Machine Learning

The integration of Artificial Intelligence and Machine Learning facilitates harnessing manufacturing data. These technologies’ assimilation in the service infrastructure and applications expedites the processing of data, thereby improving efficiency.

AI and ML-led digital transformation is boosting industrial robustness with operational streamlining via automation. Companies are actively investing in technologies that process massive data volumes in real-time and with accuracy.

Processing tons of data strengthens manufacturers to swiftly process and develop products while reducing costs and industrial waste.

- 3D Printing

3D Printing works towards developing products via digital data, wherein lasers work on materials’ coatings. Manufacturers can build prototypes with 3D Printing and troubleshoot errors to ensure seamless production at scale.

The not-so-affordable task of tooling is no more a necessity now with 3D Printing. Also, there is no need for physical prototypes.

3D Printing sharpens the competitive edge whilst giving constant feedback throughout the product launch pipeline. Making design solutions even more immersive, the intended users can get an actual feel of the product prior to actual manufacturing.

3D Printing enables mass customization and paves way for new geometries.

- Augmented Reality (AR) and Virtual Reality (VR)

Enabling the digitization of instruction manuals, AR and VR are poised to redefine mainstream industrial technologies in years to come. AR and VR can be leveraged to offer immersive training, remote assistance, and collaboration.

Together AR and VR can instruct on technical work via offering real-time instructions. These technologies can also facilitate technical support on a remote basis, and inject life in training experiences.

AR can analyze machine environments’ complications. Via computer vision, AR can give a map of machines (similar to a real-time visual manual). As a result, highly-skilled labor service turns into a “downloadable” skill. Workers can see real-time stats of the manufacturing process, with AR, to attain precision.

VR is a critical manufacturing process component applicable in technical training, remote equipment servicing, and reviews of designs.

Customized, modular, automated, and efficient are the words that describe manufacturing of the future. Industrial evolution is a pressing need that provides robust potential of boosting the returns on investment. With robotics, AI, and IoT digitization in place, data insights and smart robotics investments would boost output and lessen cost.

Asset efficiency, less machine breakdowns, and higher workplace safety would transform business models with digital transformation of manufacturing.

The Internet of Things (IoT) and Industry 4.0 have catalyzed the manufacturing revolution. These technology breakthroughs have resulted in significant changes in essential manufacturing operations, covering the path to robotics/automation. IIoT solutions may optimize any processes to deliver change, whether it is an energy market, procurement, business intelligence, or talent management. These services will help with operational excellence and execution.

Things to Know considering Industry 4.0

Industry 4.0 relates to the next wave of the 4th Industrial Revolution, which emphasizes interconnection, machine learning, concurrent data, and robotics. It is also distinguished by using automated robotics and automation in physical manufacturing and operations to build more integrated and well-connected ecosystems.

Manufacturing companies certainly take on these requirements and keep up with ever-changing consumer needs with the aid of the IIoT concept.

IoT and Industry 4.0: How This Pairing Will Drive Transformation

IoT supports the rapid expansion of Industry 4.0, in which things are connected via a shared communications link with automatic procedures. It removes or lowers the need for human assistance. Manufacturers by using real-time data analysis may enhance decision-making. Furthermore, IoT in industrial organizations ensures predictability, which decreases the likelihood of any catastrophic situation in the industry. The goal of Digital Twin is to empower Enterprise Maturity and components of information maturity to achieve an agile business, which is a key milestone in Industry 4.0.

The following are the key characteristics of IoT and Industry 4.0 in the industrial manufacturing sector:

- Manufacturing automation

- Process Improvement

- Manufacturing intelligence

- Performance evaluation

- Putting everything connected

- Gaining insights

As an important element of the fourth industrial revolution, IoT serves a critical part in the drive toward DX and Industrial Manufacturing excellence. One of the primary challenges that companies confront presently is a dearth of IT-OT convergence in their manufacturing facilities, which leads to plenty of additional issues such as a lack of plant visibility, quality, inefficiency in inventory management, and production scheduling based on demand, among others. IoT bridges the barrier between IT and OT systems by linking to lower-tier sensors, modules, equipment, Control Systems, and PLCs, as well as allowing two-way data flow to the business applications and the cloud.

Now that you’ve seen how the 4.0 of the industrial revolution happened to come, let’s look at six sectors where it’s making a significant contribution to growth.

The Major Advantages of IoT Solutions for Industries

- Convergence of IT and OT

- Prevention of production loss

- Decreases downtime

- Increases equipment utilization and calculates OEE (Overall equipment effectiveness)

- Breakdown of machinery is detected early.

- Production Enhancements and Optimization

- Plant and operational visibility in real-time

- Efficient resource usage

- Prediction and Prevention Analytics

The modern factory is transforming with new technology. The present and upcoming businesses, particularly manufacturing enterprises, are being modernized through digital transformation. While the advent of smartphones and remote work, AR has significantly expedited the manufacturing world’s digitalization.

To stay at the forefront of Industry 4.0, industrial enterprises will prefer remote help via AR in the next years. But, before we go ahead, consider where industrial firms are now and the existing issues.

Top manufacturing business current problems:

- Conventional methods of collaborating with forefront employees and field-force assistance teams are incredibly stressful.

- It is hard for service professionals to interact in person with customers to rectify problems and assure the efficient operation of machines.

- Even when there are no travel bans, it takes businesses many hours to deploy professionals to remote locations, rising in bottlenecks and unscheduled idle time.

- The point is time-consuming data collection procedure encourages field technicians to put off assembling components, operating machinery, or maintaining equipment.

How Remote Assistance may assist industrial businesses in overcoming overall obstacles:

Traditional methods of assistance and engagement are insufficient to solve new business difficulties. As the saying goes, modern problems necessitate modern solutions. An AR remote Assistance solution can aid you in overcoming current issues and driving significant advantage in the following three areas:

- Production: AR-powered Remote Assistance platform can assist manufacturers in preventing functioning challenges in their production areas and enhancing the factory’s equipment maintenance schedule. It also updates the whole manufacturing operations.

- Services: AR service applications connect field employees with industry specialists. Through video tutorials, it may support professionals to do field fixes more quickly, and raise immediate address equipment fixing leading to improve service quality.

- Training: AR can deliver interactive guidance to field staff when handling heavy machines with low dangers. It can allow them to keep their abilities more quickly and decrease recruiting budgets and the learning curve.

The Benefits of Industrial AR Remote Support

- Quick Support: The ability to give immediate help is the most crucial part of using this application. Your group of experts may offer on-demand technical assistance to clients and staff. It does not require any complicated installation or setup procedures for end-users to complete. Remote assistance may be provided on any device from any place.

- Minimize costs: Technicians can operate efficiently with the advice of professionals from any place if they have access to business remote support software. The solution saves money on traveling and allows for quick problem-solving. It also eliminates time spent traveling to and from the on-site location.

- AR Employee Training: Because remote assistance enables supervisors and staff to blend their surroundings, training may take place from anywhere. These guarantees that an industry specialist is virtually there to instruct new technicians on essential skills.

- Reduction in machine downtime: You may quickly gain access to systems via remote assistance to verify the health of the equipment and address any difficulties which result in a reduction in unplanned downtime. As a result, client satisfaction rises.

- Quality Assurance (QA): You may conduct extensive safety assessments with remote assistance software. Maintaining regulations for equipment, job locations, operator safety compliance, and so on is simple.

Summary

The very same modern technologies that enable staff one minute may be an obstacle the next, costing employers huge amounts of money every year in productivity losses, workforce dissatisfaction, and assistance.

Remote assistance is a real-time remote support service that allows enterprises to increase employee experience while lowering TCO. Augmented Reality based remote assistance allow distant technicians to interact with specialists. Experts can observe precisely what a remote technician is experiencing and contribute their experience as if they were really present enabling error-free work instructions.