fannyzeng's blog

The biggest advantage of print hardcover book is that the protective seal is strong. Which plays the role of protecting the inner pages and making the book durable. The inner pages of hardcover books, like paperback, are most threaded and nailed. And stick a cloth strip on the spine. To provide a stronger connection and protection.

There are several common forms of hardcover books:

First, according to the form of the spine, there are two kinds of the square spine and round spine

1. The square spine is thicker than the core. Due to the folding of the book's core and the cable. The height of the spine is higher than the book's core, and the more sheets printed, the more obvious. Thus, a hardcover book with a square spine should not be too thick. And it is generally suitable for the spine within 20mm.

2. Round spine, due to the different status of the front and rear book stickers. The fold of the book stickers is semicircular. Distributed on an arc surface, and balanced thickness. The flap of the core adapts to the cabochon of the spine and is concave.

Thus, thicker books are better to use round spines. The round ridge book is round after rounding the back ridge. And it is generally appropriate to use the core thickness as the chord and the arc pair at 130°.

Round ridges have two types: round-backed without ridges and round-backed ridges.

According to the material it can divide into two types. The same material from the ridge surface and a different material from the ridge surface.

1. The ridge surface is made of the same material. It is the spine and the cover and back cover are made of the same material as the whole piece. There are two kinds of ridges: square ridges and round ridges. Hardcover fabrics are paper, fabric, lacquered paper, lacquered cloth, etc.Generally equipped with protective seals.

But, there is a kind of book with a book title, pattern, etc.

Printed on the whole paper and laminated cardboard. Which is a square ridge without a protective seal.

2. Ridge surface material. The spine and cover production are in different materials. Usually with fabric as the spine. Stick the paper on the cardboard as a cover. This form is generally a round ridge without a protective seal.

A good hardcover book is not obtained by accident. And in the production process, the quality of each process needs to control. Until the final process product quality is fully qualified.

Paperback books can divide into the following due to some different processes:

(1) Wire binding paperback: a process of binding paperback books with metal wire.

(2) Sewing binding paperback. Sewing binding is a method of using an industrial sewing machine with a structure to bind books into a book. Sewing can be flat or horse stitched, with the greatest stitch pitch of 10mm and the smallest of 1.5mm.

(3) Adhesive flat packaging. It is a new binding process that emerged with the emergence of synthetic rubber. Which began to use in China in the 60s, and has had wide use since then. There are two types of adhesive binding: cold adhesive and hot melt adhesive.

(4) Cord bonding. This is a higher-grade binding method. Which is more used for books with higher reading frequency and thicker books.

Its characteristic is that the binding line passes through the fold of the book post. And then locks all the book posts together with a thread. And after the back of the book is glued, wrapped and wrapped, ironed, and dried. Cut three sides, and all the binding work of a book is complete.

The difference between hardcover book printing and paperback printing.

Hardcover books are high compared with paperback books. Using hard paper, fabric, leather, plastic, etc. As covers, and some books are also clothed on the back. This means the process of hardcover book printing is very complex and demanding. The paperback method is simple, the cost is low, suitable for books with a small number of pages and a large number. The main processes of simple packaging are folding, sheet matching, and staple cover. And cut book edges, and the cover of such books is generally paper.

Whether it is hardcover printing or paperback printing. The production of a book will consist of two parts: printing and binding. And for hardcover books and paperbacks, the printing process is the same. There is not much difference. It's that hardcover book printing requires higher quality. So the paper used is generally high-grade, better paper. And paperback books can use ordinary paper.

Chinaprinting4u with over 20 years of book printing in china. We support many kinds of hardcover and softcover book printing. Offers the best quality book printing services at the most competitive price. Choose us to print your own book here.

With the continuous development of the printing industry, traditional printing faces many challenges. Which trends will the printing industry develop in the future? Today let us talk about the development trend of the printing industry in the future from 6 aspects.

1. Printing online

Book printing factories face the strong competitiveness. In response to the gradual increase in market customer demands. Printing companies are more "scheming" in getting an order. Most of the printing factory are transfer online printing service from traditional mode. Meanwhile, provide various of personal customs to meet the market needs. Printing online can on-time communication. So that to reduce the communication time and cost, then to short the order making cycles. Printing online has become a big trend of printing industry.

2. Green printing technology becoming the major trend

Waterless offset printing ink, soy ink, etc replace the traditional printing ink. Waterless offset printing ink don't need to use the fountain solution. It can save a lot of time to adjust the machine and reduce the waste of master paper. Besides, its unique planogravure structure also provides better control over dot gain and fineness of imaging. Because waterless printing reduces the production of various waste liquids in printing. It has always been advocated by environmental protection.

Soy ink is made from soybean oil. It is green printing ink. In the printing process, it doesn't production any pollution. Soy ink is more suitable for children's book printing. Even if the little baby bites the book. It can't harm children's health. So soy ink is also the trend in the printing industry.

3. Use data to control cost and environment

The management and the classification of the company's waste according to the inventory figures. It will reduce costs and protect the environment through these two aspects. "First, use the numbers 0 to 15 to demarcate the position of the item. And start from the largest number 15 when taking the item. For example, for the ink, at least three days of production must be guaranteed. When the number reaches 4, it is exactly three days. If the stock quantity is not enough, we need to fill in the order card. And then re-order from the goods supplier to ensure that the stock quantity is available for 3 days. Other production materials are managed in this way. But the stocks of different production materials are guaranteed. There are some differences in the amount.�?Besides, the various wastes that are constantly generated by the factory are also being recycled. In 2005, the advanced Japanese company Jinyangsha reduced organic solvents from 28 to 26, from 26 to 24 in 2006, and from 24 to 10 in 2007. The organic solvents still in use so far. There are 10 more, and several organic solvents are being tested to achieve the purpose of continuous reduction.

4. A New Era of True Color Printing

Sakata Kiyoshi, deputy director of the Technology Department of Fuji Starlight Printing Equipment (Shanghai) Co., Ltd. He believes that in the future printing trend. Printing companies will import and use two more technologies. One is waterless printing, and the other is a new generation of inkjet digital printing machines. To fully reproduce the original tonal range.

5. Use color management system to save ink.

Through GMG's InkOptimizer system, it can reduce the amount of ink applied to the page by calculating the amount of color conversion from CMYK (note: it is a four-color printing color mode) to CMYK. While ensuring Ink quality, improved printing conditions. Under the control of this system, the automatic reduction of the color ink volume reduces the overall ink volume of the printing to more than 25%. While significantly reducing the drying time and the preparation time of the printing job. Thereby improving the productivity.

6. Wide color gamut printing will be widely used.

With the popularization of original input using digital cameras. The widespread use of inkjet printers. And the construction of RGB (note: three-color printing color mode) digital workflow system. Wide Color gamut printing will be widely used in the future printing.

At present, in the context of economic globalization. The development of the printing industry. It is developing in the direction of green, service, high efficiency, digitization and intelligence. New products, new technologies, new service areas, and new business models continue to emerge. Technology research and development processes are accelerated . technology and product life cycles are continuously shortened. And technology cross-integration and technology integration are developing rapidly.

These changes have a large impact in the traditional printing industry. In the era of big data, the printing factories must break away from tradition mode. And move towards the road of high-tech innovation.

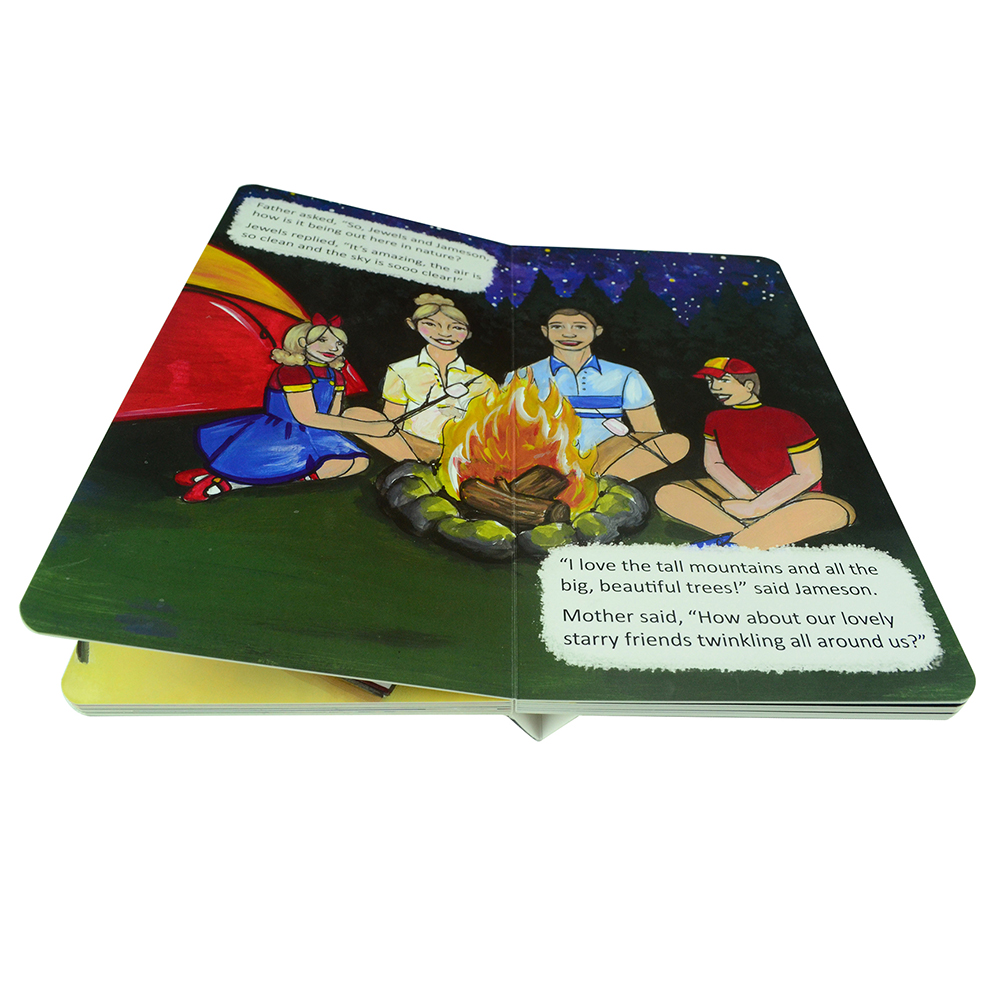

When we custom board book printing, the paper selection is the key to printing quality. Select the suitable printing paper will make your book more colorful and attractive. Today, we through 5 parts to discuss which paper is best for board book printing.

1. Color reproduction

Print board book often with a lot of color images in the books. So custom print board books will have a high standard for color reproduction.

Coated one side paper (C1S) after coating and glossy, the surface with the advantage of flat, glossy and smooth. This kind of paper with high color reproduction, bright luster, uniform coating, fast ink absorption, good print ability, strong 3D effect. Even use the ordinary ink, it also can achieve the high quality printing effect.

Matte art paper, also called matte coated paper or uncoated paper. The paper’s surface is also flat and smooth. The color reproduction is the same as C1S. Use the matte art paper to print the image, the color is not glossy as C1S. But the images are more exquisite and high-end.

Offset paper is more suitable for black and white printing. If do color printing, the color reproduction is not good as C1S and matte art paper.

2. Glossy

Custom board books, if the book color is matte, it is not easier to attract the children to read. Offset paper and matte art paper are uncoated. But C1S with coating, use it to print the board books, book surface with glossy, will make the book look more bright and colorful. Compared to print the pattern on offset paper or matte art paper. Print the pattern on C1S, it is more easier to catch children’s eye.

3. Tear resistance

Offset paper is often made of low-value raw materials. Such as straw pulp, which is relatively easy to damage. Coated one side paper and matte art paper is high-density paper, which uses high-value raw materials. Such as cotton and bark, and is relatively not easy to damage. besides, coated paper has relatively high requirements for flatness and whiteness. And it looks more beautiful, smooth and white.

The readers of the board book often are little children. They just start to read and don’t know how to protect book. Besides, they have the habit of bite or tear the book. If use the offset paper to custom children’s board book printing. Once the children bite or tear the book, it is easier to damage. But coated one side paper and matte paper can prefect solve this problem. Even the children bite or tear the book, it is hard to damage.

4. Paper price

Matte art paper is thinner and whiter than coated paper, more ink-absorbing, and harder. It is not easier to deform like coated paper and offset paper. But if use matte art paper to print board books, the cost will be more high than coated paper and offset paper.

5. Board book characteristic

Printing board books often need to print one side. Because after printing, the board book binding is, mount two papers together. So its characteristic decide it doesn’t need to print double side.

To sum up, combine with the above 5 aspects. If use the matte art paper to print board books. Although it can prefect restore the artwork and not be easier to deform. But the pattern was not as bright as printed on coated one side paper. And the cost is too high. If use offset paper for board book printing, the color reproduction, glossy, tear resistance, etc is not good as coated one side paper. Thus, whether from the consideration of cost or printing effect. Coated one side paper is best for custom board book printing services. Sometimes, to make the board book look more thick. The board book printer will suggest clients to choose 1mm gray board or more thick gray board to increase the thickness.

Children's book printing is most popular items in the printing industrial. While choose the type of book finishing, maybe you can consider the binding way at the beginning.;

So what kind of binding way that most companies available?

Priority option should be softcover, which is cheaper and simple.

Softcover book usually require 250gsm-350gsm thickness of the cover, with lamination outer and some choose special finishing like embossing, debossing, foiling stamping, or spot UV.

Inner usually use 157gsm because the page count of children's book are less, such as 24pages, 32pages. These material for binding a paperback, it is perfect.

If you consider a premium product, board book is the one. Custom board book printing, it is use almost thickest printed board 350gsm and 2 pieces mounted together. So every spread page are connect together, so it no need glue on the spine, just page back to back, and because is spread page, so it can be laid flat, which is nice looking and easy for kids to flap over.

The third option is also popular for book author to choose, it is hardback--case bound method.

This use very thick board for the cover and inner just regular paper thickness, like 157gsm or 200gsm etc.

Interior pages are section thread stitching then glue into the case (hard cover), so the hard cover is for protect inner pages and usually be larger.

These are the binding options of regular children's book printing, which are most factories use to do with.

A good magazine can take an large impact for the promotion of company. When we printing magazine, not only need to design the content well, also need to select the correct paper. Otherwise, it can't bring the promote effect and will take a bad effect. So, when we custom magazine printing, we need to select the suitable paper.

In printing, magazine printing is more easier appear the problem of incomplete or blurry patterns. This is mainly due to the printing problems of the printing ink. Besides, it also depend on the printing paper choice. Different types of magazine, the standards of paper choice is different. Following are some standards for different types of magazine printing.

1. For the high-end theme of cloths and life magazine printing. The printing paper is often select over 70gsm of coated paper or medium size coated paper.

2. For the high quality monthly and professional magazines printing. The printing paper is often select mid-grade coated paper or high whiteness of light weight coated paper. And the gram weight of paper is often select equal or over 70gsm.

3. For the ordinary quality of monthly or weekly magazine printing. Like such kinds of cheap magazine printing. The printing paper is often select high brightness coated paper or light weight coated paper. And the gram weight of paper is often select equal or over 60gsm.

4. For the large circulation of weekly and comprehensive magazine printing. The printing paper often select light weight coated paper or calendar paper. And the gram weight of paper is often select equal or over 65gsm.

Apart from the choice of magazine printing paper. The magazine quality is good or bad, it is also depend on the printing details are correct or not. Such as the reprint of the corner version and the color version. Whether the color separation is correct. Whether there are black spots on the page, etc.

If you can deal with these details well, the magazine will be more than half the battle. But, select a good magazine printing factory is also very important. Because a good printing factory. Not not can ensure your magazine printing quality, also can help you save a lot. And high quality magazine printing can better for the promotion of company and product. Meanwhile, the readers also can get the message what they want.

ChinaPrinting4u is a leading printing factory in China. We imported the most advanced cutting, printing equipments. And hired the rich experience of technical experts. So that we can make sure 100% supreme quality printing. Besides, for the magazine printing paper, binding, surface, etc issue. We also can give you some suggestions. Now, contact us to get an inquiry.